Choosing the Right Folding Mask Machine : A Buyer’s Guide for Factories

As global demand for protective masks continues to grow, more factories are investing in reliable KN95 mask machines, N95 folding mask machines, and automatic mask production lines to improve productivity and meet strict quality requirements. However, with so many models and folding mask machine suppliers on the market, choosing the right equipment is a critical decision that affects long-term efficiency and product performance.

This comprehensive buyer’s guide will help you understand the key factors when selecting a 3D folding mask machine, also known as a fish-shape or KN95 folding mask machine, suitable for both medical and industrial protection masks.

1. Production Capacity & Operational Stability

When selecting a folding mask machine, production speed and reliability are major considerations. High-speed output is valuable only when the equipment remains stable during long operations.

Key evaluation points:

-

Continuous high-speed production with minimal downtime

-

Low defective rate and material waste

-

High precision ultrasonic welding for earbands and edges

-

Fully automated feeding, folding, shaping, and cutting functions

A well-designed fully automatic mask machine maximizes ROI and allows you to meet increased market demands quickly.

2. Quality Standards & Mask Precision

KN95/FFP2 and similar protective masks must meet strict safety certifications, especially in medical environments. Therefore, the machine must ensure that every mask maintains consistent structure and performance.

Critical quality features:

-

Accurate folding design for better face fit

-

Stable welding to prevent ear loop breakage

-

Precise positioning of melt-blown layer and outer fabrics

-

Smooth edges and clean appearance

Choosing equipment with advanced ultrasonic systems and intelligent tension control will help you comply with global standards such as CE, FDA, and GB2626-2019.

3. Automation Level & Ease of Operation

Modern manufacturing emphasizes labor reduction and operational simplicity. A high-quality automatic mask production line typically includes:

-

Automatic material alignment and real-time correction

-

Touch-screen programmable control for easy operation

-

Fault detection with alarms and auto-stop

-

Quick mold change and simplified maintenance

Even new operators can quickly master a fully automatic folding mask machine, enhancing productivity with minimal training time.

4. Flexibility for Multiple Mask Types

As consumer preferences evolve, machines should support various product formats to stay competitive. When planning investment, check whether the machine can:

-

Produce KN95, N95, and 3D fish-shape folding masks

-

Adapt to different layers and filter materials

-

Support options for nose bridge strips, breathing valves, printed logos

-

Switch easily between adult and children mask sizes

A flexible system ensures rapid response to market upgrades without additional major equipment purchases.

5. Strong Technical Support & Supplier Reliability

Mask machines operate at high intensity, so dependable after-sales service from your folding mask machine supplier is essential.

Supplier checklist:

-

Professional installation and operation training

-

Fast spare-parts delivery with global support

-

Remote diagnostics and repair assistance

-

Sufficient warranty and lifetime technical service

Reliable partners help reduce risk, ensuring continuous and compliant production.

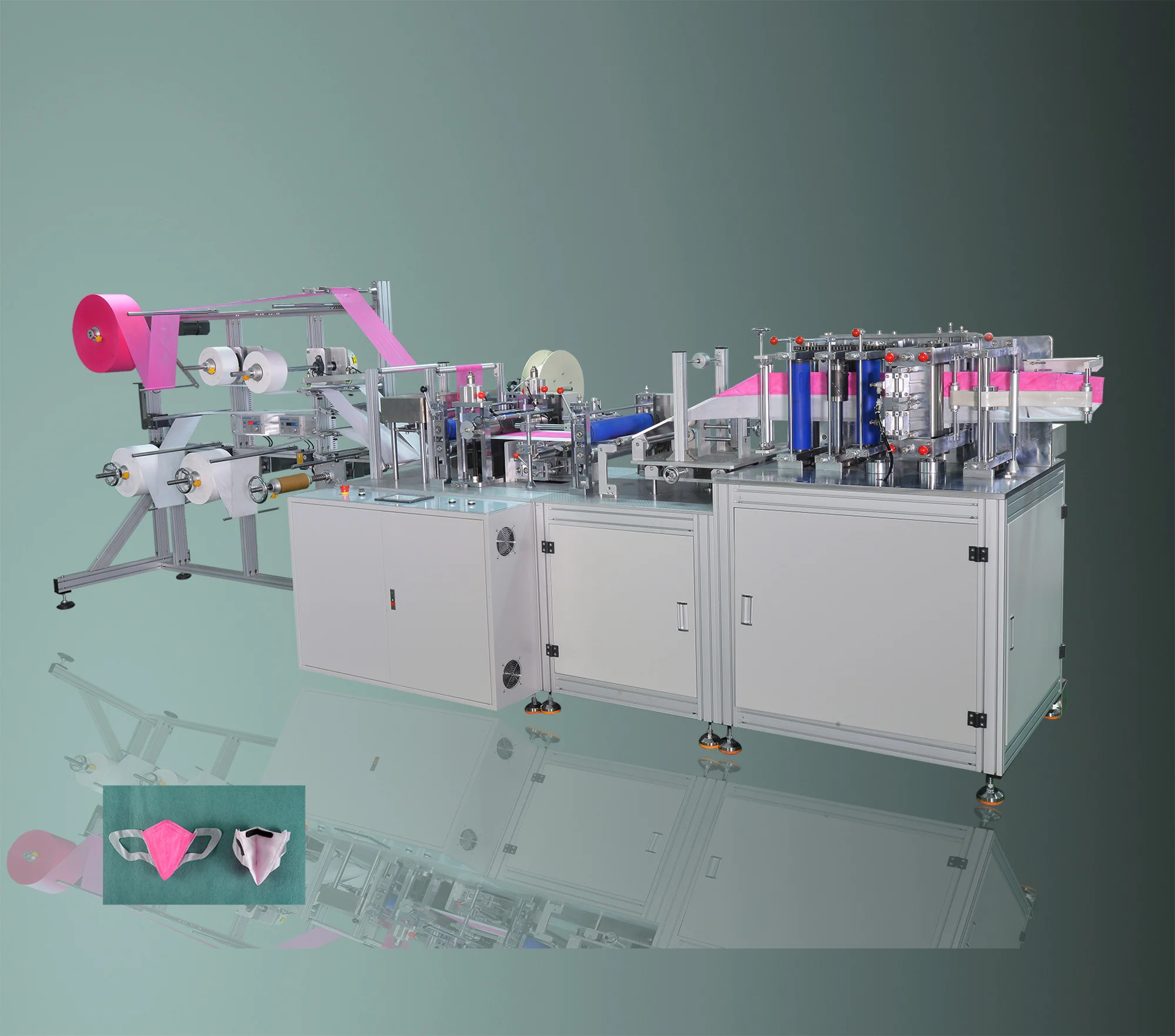

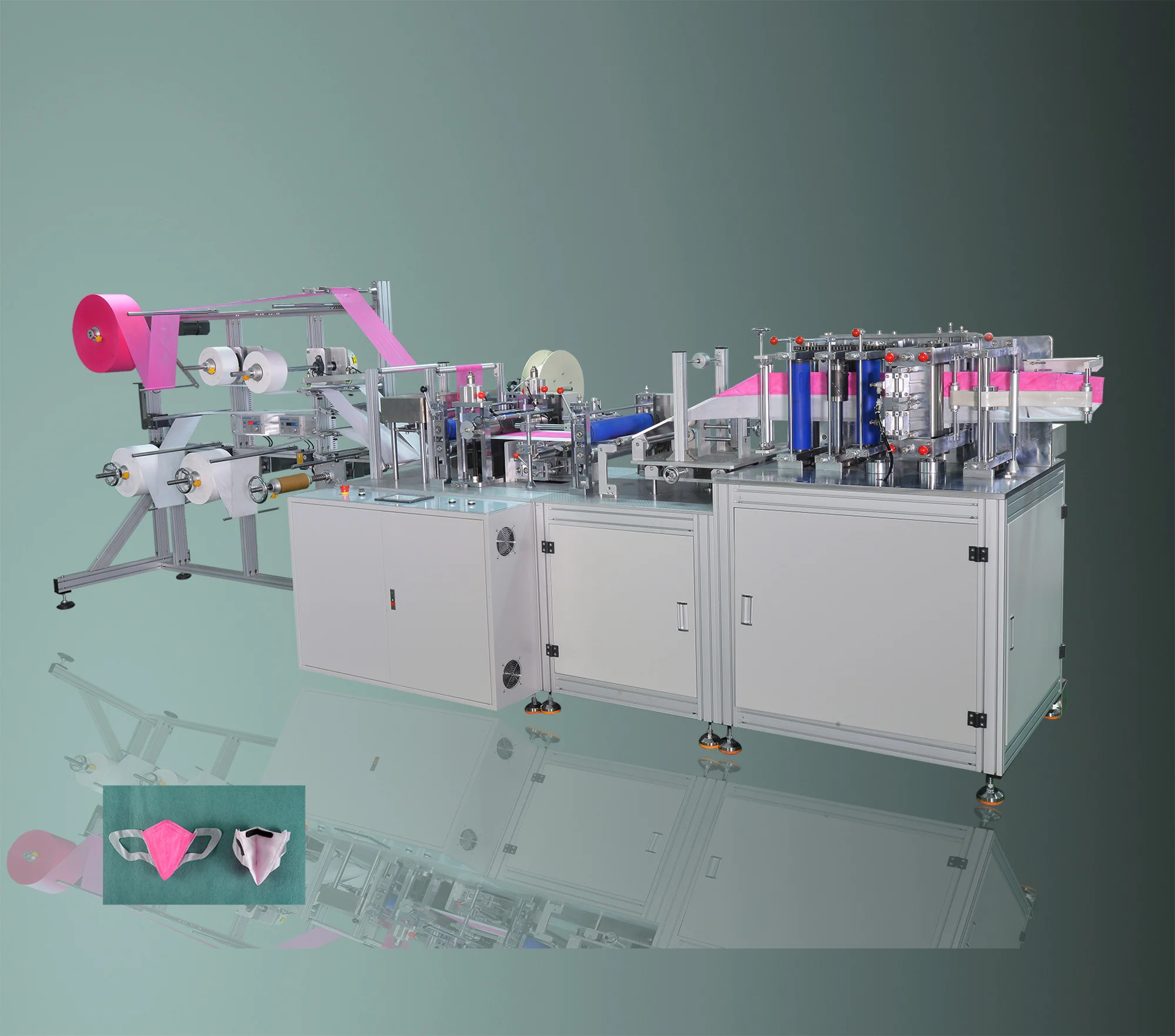

Broadfair Automation — Your Trusted Mask Machine Manufacturer

Broadfair Automation Equipment Co., Ltd. is a high-tech enterprise integrating R&D, manufacturing, and sales of intelligent mask equipment. As a professional KN95 mask machine and folding mask machine supplier, Broadfair provides:

High-speed, stable N95/KN95 folding mask machines

Fully automated operation and intelligent control systems

Customizable specifications for various mask shapes and sizes

Strong engineering support & global after-sales service

Strict quality control to ensure high-standard performance

Their equipment has been widely applied in medical mask manufacturing equipment markets worldwide, helping factories boost output while meeting international requirements.

Extra Purchasing Tips for Factories

Before purchase, it is recommended to:

-

Visit the supplier for a live demonstration

-

Check core components such as ultrasonic welders, servo systems, and sensors

-

Compare energy consumption and maintenance costs

-

Confirm compliance with the target market’s certification standards

Small details will significantly influence long-term production performance.

Conclusion

Choosing the right KN95 folding mask machine is not just about buying equipment—it is a strategic decision that affects your factory’s productivity, competitiveness, and ability to meet global safety standards. By focusing on speed, precision, automation level, equipment flexibility, and supplier reliability, managers can make informed decisions for long-term success.

Whether you are upgrading your automatic mask production line, expanding capacity with an N95 folding mask machine, or seeking a reliable folding mask machine supplier, Broadfair Automation Equipment Co., Ltd. is ready to support your growth with professional technology and innovative solutions for the future of mask production.

Folding Mask Machines Explained: Key Functions and Operational Advantages

www.broadfairmachine.com

Broadfair Automation Equipment Co., Ltd.