Exothermic Weld Connection: A Revolutionary Solution for Reliable Grounding Systems

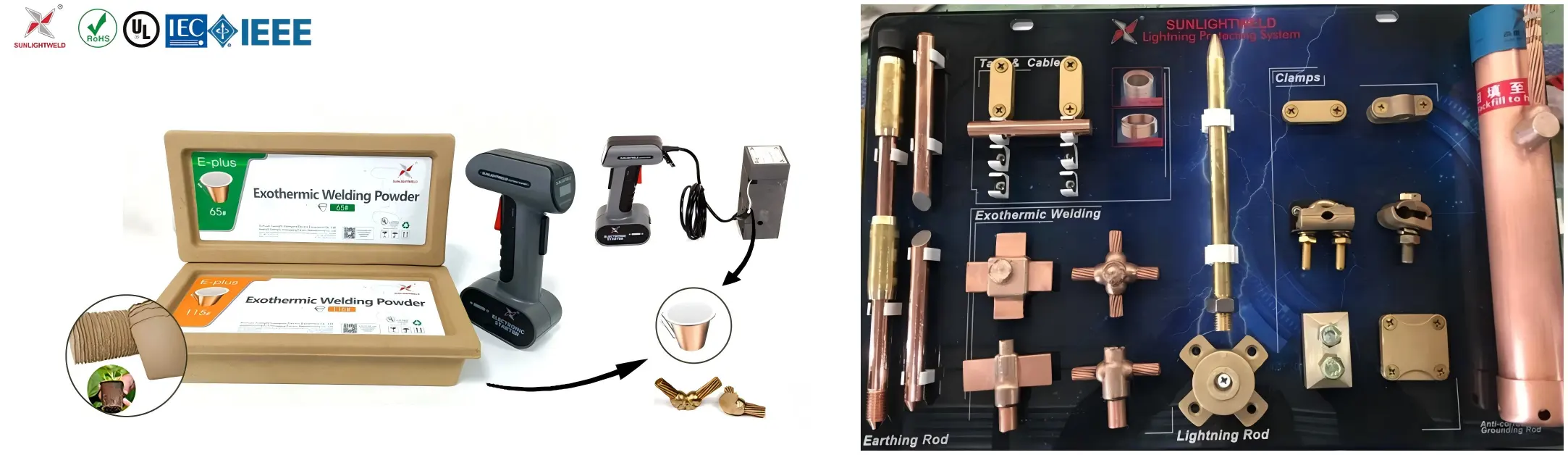

Grounding systems are crucial for ensuring the safety and stability of electrical infrastructures. They play a vital role in protecting both equipment and individuals from electrical faults and lightning strikes. One of the most important methods for making secure and reliable connections in grounding systems is through exothermic welding. Exothermic weld connections are known for their exceptional electrical conductivity, durability, and corrosion resistance, making them an ideal choice for various industries, including power distribution, telecommunications, and transportation.

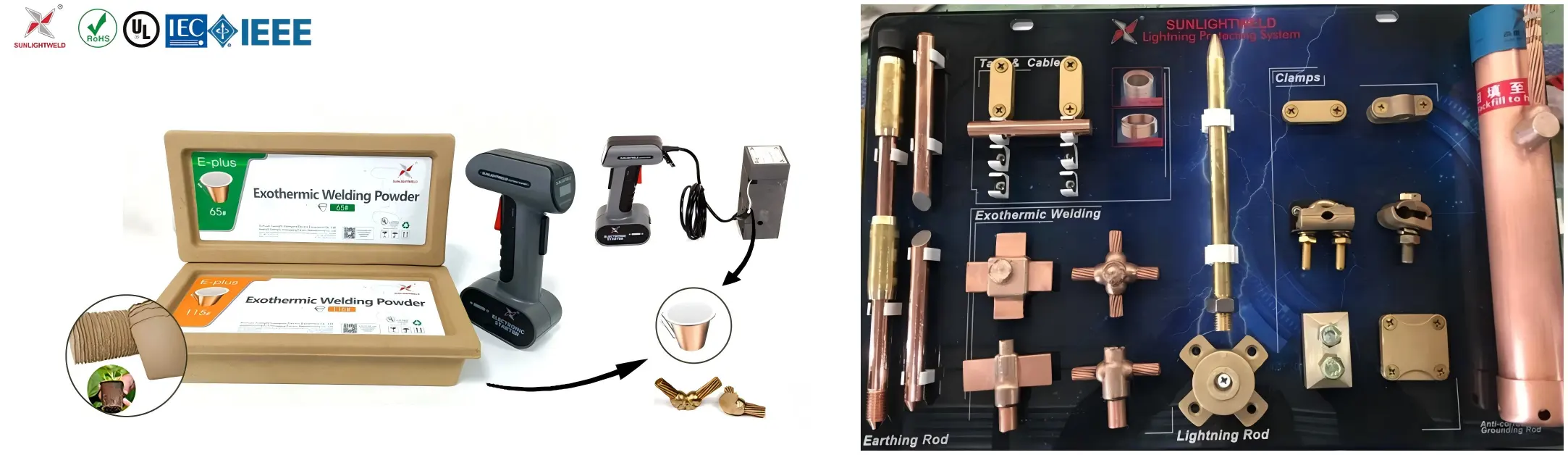

Among the leaders in exothermic welding technology is Sunlightweld, a leading supplier, manufacturer, and factory of earthing materials, grounding products, and lightning protection systems. Sunlightweld has revolutionized the exothermic welding process by offering cutting-edge solutions, such as its eco-friendly electronic ignition exothermic weld connection, which boasts multiple certifications and exceptional features that set it apart from other products in the market.

This article will delve into the benefits and advantages of Sunlightweld exothermic weld connection, focusing on its certifications, eco-friendly ignition system, economic efficiency, and compatibility with existing molds. We will also explore how Sunlightweld is transforming the industry and making its mark globally through its commitment to quality, innovation, and customer satisfaction.

What are Exothermic Weld Connections?

Exothermic welding is a process that uses a chemical reaction to produce a high-temperature reaction that fuses two conductors together, creating a permanent and highly conductive joint. This method is widely used in grounding systems, where the connection's reliability and conductivity are critical. Exothermic welding creates a solid connection that resists corrosion and ensures long-term electrical performance, making it essential in applications where safety is paramount.

The process involves the use of a mold that holds the materials to be welded, along with a special exothermic powder that generates the required heat when ignited. The molten material flows into the mold, bonding the two conductors together to form a durable and low-resistance connection. The result is a robust, high-quality joint that requires no further maintenance, which is why exothermic weld connections are the preferred choice for grounding applications worldwide.

Sunlightweld Exothermic Weld Connection Certification Patent

One of the key reasons for Sunlightweld's prominence in the industry is its commitment to quality and adherence to international standards. Sunlightweld exothermic weld connections have earned multiple certifications, including IEEE837, UL467, IEC62561-1, CE, and ROHS certifications. Among these, the IEEE837 and UL467 certifications stand out as the gold standard for grounding and bonding products in the United States and globally.

The IEEE837 certification ensures that the exothermic weld connection meets stringent requirements for electrical conductivity and safety, while the UL467 certification signifies that the product complies with the highest safety standards for grounding and bonding applications. These certifications provide customers with the assurance that Sunlightweld's products meet or exceed industry standards for reliability and safety.

In addition to these certifications, Sunlightweld has also secured American patents for its innovative eco-friendly electronic ignition exothermic weld connection, highlighting its commitment to technological advancement and product differentiation. These patents allow Sunlightweld to offer exclusive solutions that are not only highly efficient but also environmentally friendly, making them the preferred choice for businesses looking for sustainable grounding solutions.

Sunlightweld Electronic Ignition Exothermic Weld Connection: A Game-Changer

Sunlightweld has taken the exothermic welding process to the next level with its eco-friendly electronic ignition exothermic weld connection. This innovative product offers several unique features that make it stand out in the market:

1. Type-C Charging: Environmentally Friendly, User-Friendly, and Safe

One of the standout features of Sunlightweld exothermic weld connection is its Type-C charging, which ensures that the ignition system is both environmentally friendly and user-friendly. The Type-C charging feature allows for quick and efficient charging, and the system is designed to be fully safe for use in all environments. The eco-friendly ignition system reduces the reliance on disposable batteries, providing a more sustainable and cost-effective solution for customers.

Additionally, Sunlightweld's EPLUS system design makes it incredibly easy to use, requiring minimal training to achieve professional results. Whether you are new to exothermic welding or an experienced user, the system's intuitive interface ensures a seamless and efficient operation.

The ignition starter is also highly durable, offering excellent waterproof performance (IPX3) and shock resistance, making it an ideal choice for industrial and outdoor applications. Whether the application is in extreme weather conditions or rough industrial environments, Sunlightweld's ignition system guarantees reliable performance and long-lasting results.

2. Economic Efficiency with AI-Driven IoT Platform

Sunlightweld eco-friendly electronic ignition exothermic weld connection is not just an environmentally sustainable product; it is also highly economic and efficient. Paired with Sunlightweld's AI-driven IoT platform, this system brings a revolutionary level of efficiency to the exothermic welding process.

The EPLUS ignition system enables fast ignition, allowing for welding to begin in just seconds, which saves about 70% of the operational time compared to traditional welding methods. This significant reduction in operation time leads to improved productivity and higher welding throughput, which is essential for large-scale projects where time and cost efficiency are crucial.

Moreover, Sunlightweld's direct factory pricing ensures that customers receive the most competitive pricing in the industry. Based on feedback from international customers, Sunlightweld's products provide at least 30% higher profit margins compared to other brands, making them an excellent choice for businesses seeking cost-effective grounding solutions.

3. Compatibility with Other Brands' Molds

Another significant advantage of Sunlightweld eco-friendly electronic ignition exothermic weld connection is its compatibility with molds from other brands. If you already have existing molds from other manufacturers, there's no need to worry about compatibility issues. Sunlightweld's system works seamlessly with molds from other brands, allowing for a smooth transition without the need for expensive replacements.

This flexibility makes Sunlightweld exothermic weld connection an ideal choice for businesses looking to upgrade their welding systems without completely overhauling their existing infrastructure. It helps save both time and money while still delivering top-notch performance and results.

Sunlightweld: Your Trusted Partner in Grounding Solutions

Sunlightweld is a leading supplier, manufacturer, and factory of earthing materials, grounding products, and lightning protection systems. With a strong commitment to innovation, quality, and customer satisfaction, Sunlightweld has built a solid reputation for providing reliable and cost-effective grounding solutions across industries.

The company's factory-direct pricing and Chinese supply chain advantages give Sunlightweld an edge over competitors. Customers benefit from competitive pricing, ensuring that they can achieve higher profit margins compared to other brands. Sunlightweld's ability to deliver high-quality products at cost-effective prices has earned it a loyal customer base in both domestic and international markets.

As part of its global expansion strategy, Sunlightweld is actively developing partnerships around the world, bringing its advanced products and services to new markets. The company's innovative approach and commitment to customer satisfaction make it an ideal partner for businesses seeking reliable and sustainable grounding solutions.

Sunlightweld exothermic weld connections represent a breakthrough in grounding technology, offering outstanding performance, reliability, and efficiency. With certifications such as IEEE837 and UL467, and the patented eco-friendly electronic ignition system, Sunlightweld has set a new standard for exothermic welding in the industry. Whether you're looking for improved operational efficiency, reduced costs, or a more sustainable grounding solution, Sunlightweld's products deliver exceptional value and performance.

By offering direct factory pricing, compatibility with other brands' molds, and advanced features like Type-C charging, Sunlightweld continues to lead the way in providing innovative and cost-effective earthing solutions for a wide range of industries.As Sunlightweld expands its global presence, it remains committed to supporting its partners and customers with the best grounding solutions, ensuring safety and reliability in every project.

https://www.sltup.com/Exothermic-Welding

https://www.sltup.com/Electronic-Ignition-Exothermic-Welding-Wholesale-And-Factory-Price.html

www.sltup.com

Sunlightweld