How to Choose the Best Electrically Conductive Tape for Your Project

In the fast-evolving world of electronics and electrical engineering, electrically conductive tape plays a vital role in ensuring efficient performance, stable conductivity, and reliable assembly. Whether used for electromagnetic shielding, grounding, or bonding conductive surfaces, selecting the right conductive tape can make a significant difference in your project’s success. In this article, we’ll explore how to choose the best electrically conductive tape for your needs, drawing insights from Dongguan Xuanjie Electronic Products Co., Ltd., a leading manufacturer specializing in advanced adhesive materials for electronic and electrical applications.

1. Understand What Electrically Conductive Tape Is

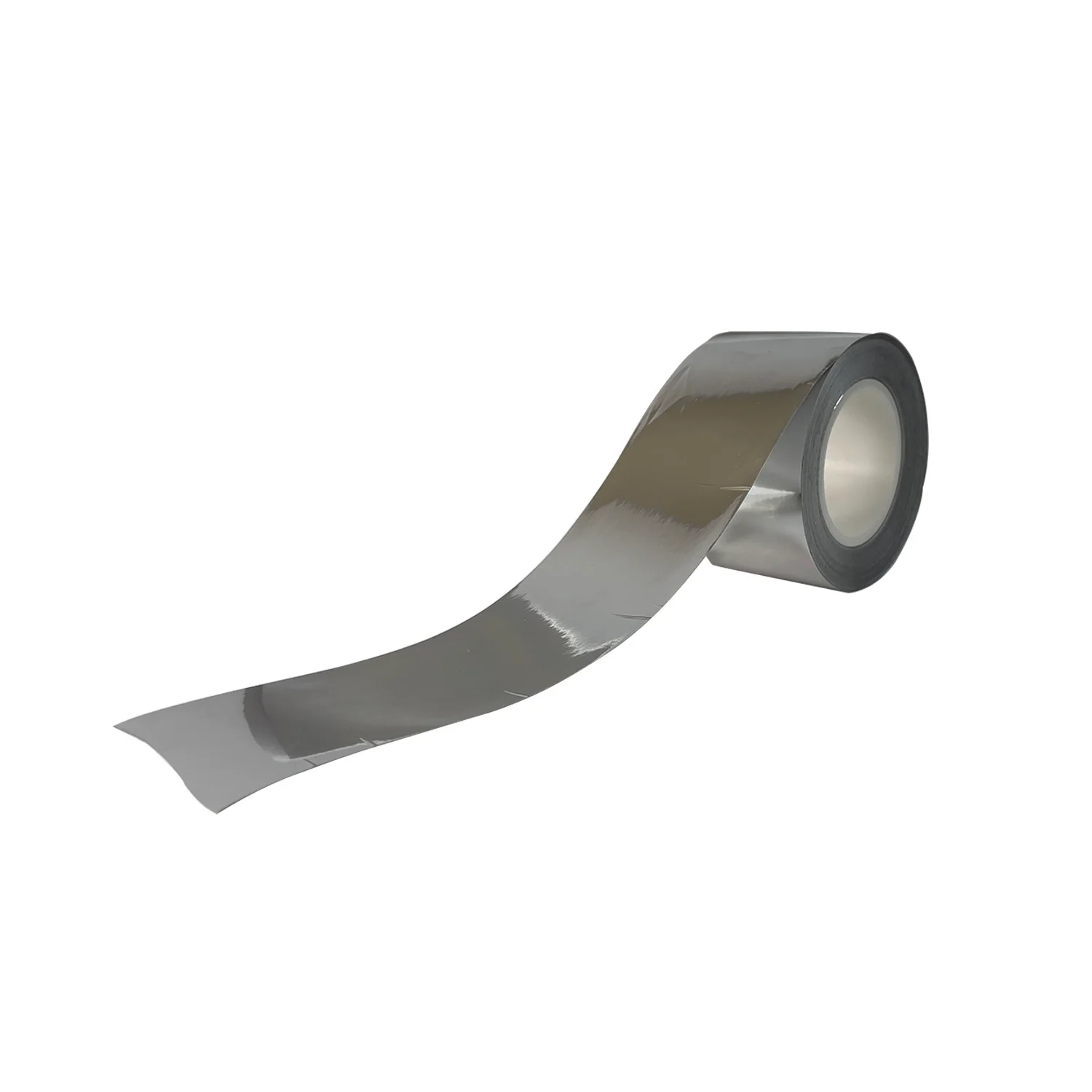

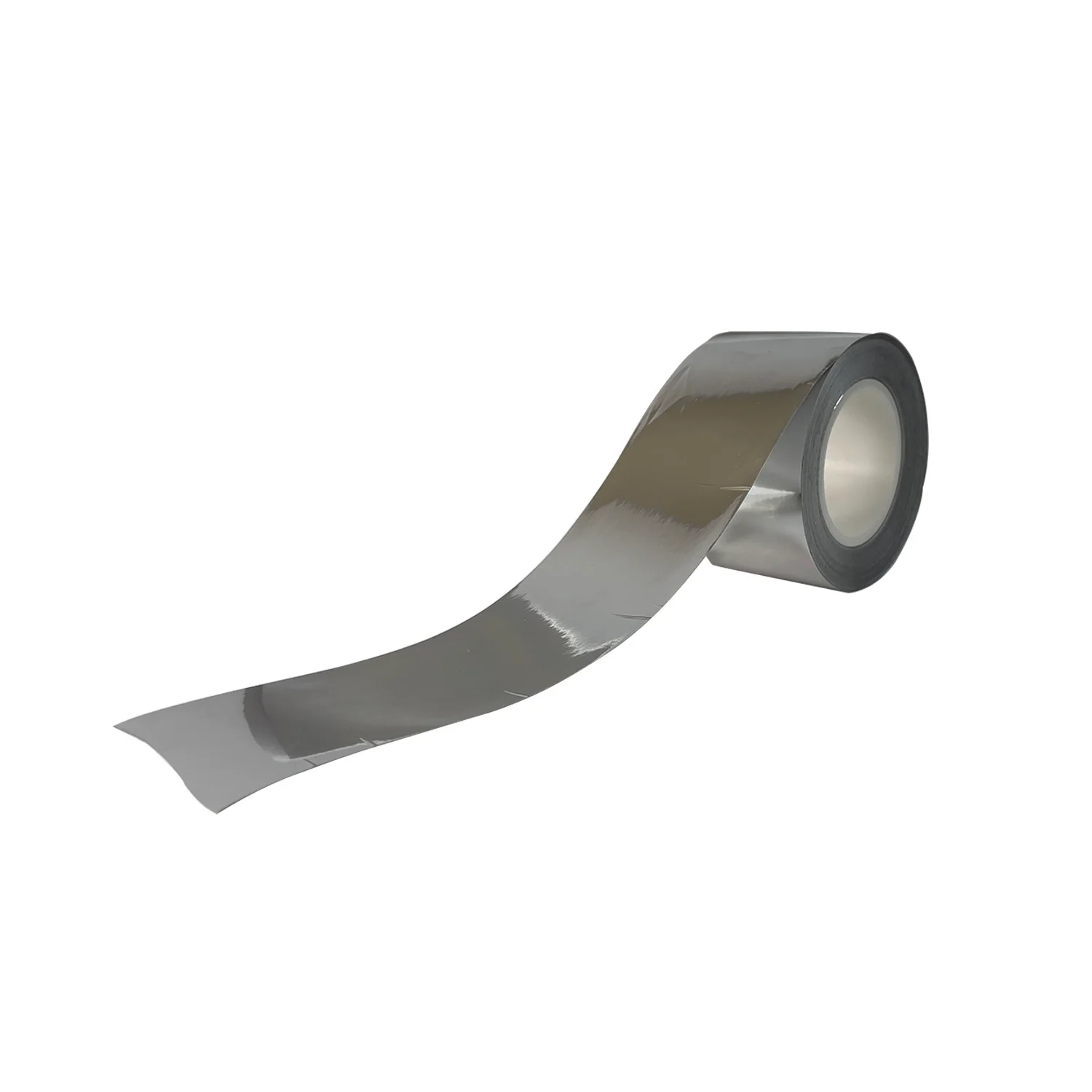

Electrically conductive tape is a type of adhesive material that allows electricity to pass through it. It’s typically made by coating a conductive metal (such as aluminum, copper, or nickel) onto a flexible backing and applying a conductive adhesive layer. This structure enables it to connect components, reduce electrical resistance, and provide shielding against electromagnetic interference (EMI).

Dongguan Xuanjie Electronic Products Co., Ltd. has developed a wide range of conductive and specialty tapes designed to meet the diverse needs of electronics manufacturers. Their products, including black double-sided tape, black-and-white double-sided tape, and repair tapes, are engineered for precision and reliability in both consumer and industrial electronics.

2. Determine the Type of Conductivity You Need

Conductive tapes can be electrically conductive through the adhesive (adhesive-to-adhesive) or conductive only through the backing material (surface conduction).

-

Adhesive-to-adhesive conductive tape is ideal for bonding two conductive surfaces while maintaining electrical continuity.

-

Surface-conductive tape works best for applications where grounding or EMI shielding is required, such as in enclosures or circuit assemblies.

Choosing the correct type ensures that your circuit or component maintains consistent conductivity without adding unnecessary resistance.

3. Consider the Material and Backing Type

The choice of backing material affects both performance and durability:

-

Copper foil tape provides excellent conductivity and easy soldering.

-

Aluminum foil tape offers strong EMI shielding and is lightweight.

-

Fabric or conductive cloth tape is flexible and ideal for irregular surfaces or wearable electronics.

Dongguan Xuanjie Electronic Products Co., Ltd. uses high-quality raw materials and automated production equipment to ensure that each roll of tape delivers uniform conductivity, strong adhesion, and long-lasting performance. Their materials undergo strict compliance testing to meet the safety and quality standards required in modern electronics manufacturing.

4. Evaluate Adhesive Strength and Temperature Resistance

The adhesive strength of conductive tape determines how well it bonds to surfaces under different environmental conditions. For projects involving heat or vibration, look for tapes with high-temperature-resistant adhesives and stable conductivity under stress.

Xuanjie’s advanced production technology ensures that its specialty tapes maintain strong adhesion and stable conductivity even in high-demand conditions, making them suitable for both laboratory testing and mass production in industrial environments.

5. Check for EMI and ESD Protection Needs

If your project involves sensitive electronic components, EMI (electromagnetic interference) and ESD (electrostatic discharge) protection are critical. Electrically conductive tapes are often used to shield circuits, cables, and devices from unwanted interference.

Choose a tape with proven EMI shielding effectiveness and ESD-safe properties to protect your devices from performance degradation. Xuanjie’s conductive tapes are engineered for such demanding environments, ensuring excellent protection and stability for advanced electronic assemblies.

6. Match the Tape Width and Thickness to Your Application

Different applications require different dimensions:

-

Thin tapes (under 0.1 mm) are suitable for compact devices or flexible circuits.

-

Thicker tapes (above 0.1 mm) provide enhanced mechanical strength and are ideal for grounding or EMI shielding of enclosures.

Selecting the appropriate width and thickness ensures proper fit, contact area, and mechanical stability.

7. Prioritize Quality and Testing

When selecting conductive tape suppliers, prioritize manufacturers that invest in testing, research, and automation. Dongguan Xuanjie Electronic Products Co., Ltd. is equipped with multiple compliance testing instruments and fully automated production lines, ensuring consistent quality and performance across every batch. Their commitment to innovation and customer satisfaction enables them to meet diverse requirements across industries—from consumer electronics to automotive and communication equipment.

Conclusion

Choosing the best electrically conductive tape involves balancing several factors—conductivity type, adhesive strength, material composition, and application requirements. By understanding your project’s needs and sourcing from a trusted manufacturer, you can achieve better electrical performance and long-term reliability.

Dongguan Xuanjie Electronic Products Co., Ltd. stands out as a professional developer and producer of electronic adhesive materials, combining automated precision manufacturing with strict quality control. Whether you need conductive, double-sided, or specialty tapes, Xuanjie provides tailor-made solutions that ensure your products perform with precision, stability, and confidence.

www.dgxjdz.cn

Dongguan Xuanjie Electronic Products Co., Ltd.