Top 5 Factors to Consider When Choosing an Extruder

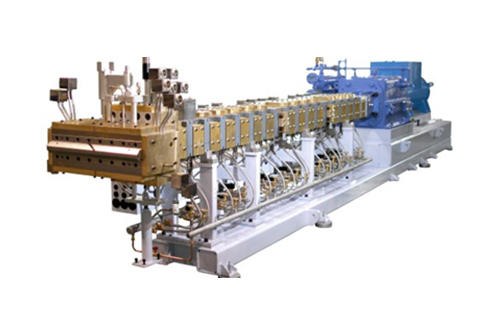

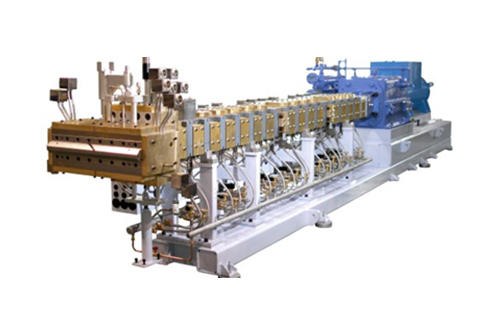

Choosing the right extruder is a critical decision for manufacturers working in plastics, chemicals, new materials, batteries, electronics, and environmentally focused industries. An extruder is not just a standalone piece of equipment; it is the core of a production line that directly affects product quality, energy efficiency, production stability, and long-term operating costs.

With the rapid development of new materials,new energy, and green manufacturing, extruder selection has become more complex than simply matching output capacity. Manufacturers now need to consider process adaptability, digital integration, sustainability goals, and the ability to customize systems for specific applications.

Drawing on practical engineering experience and integrated solution capabilities, this article outlines the top five factors you should consider when choosing an extruder, with insights aligned with the system integration approach of Being (Shanghai) Intelligent Technology Co., Ltd.

1. Material Characteristics and Process Requirements

The first and most fundamental factor is a clear understanding of the material you plan to process and the final product requirements.

Different materials behave very differently inside an extruder. Thermoplastics, thermosetting materials, polymer composites, battery materials, electronic chemicals, and environmentally friendly materials all require specific screw designs, barrel configurations, and temperature control strategies.

Key questions to clarify before selection include:

-

Is the material heat-sensitive or shear-sensitive?

-

Does it require intensive mixing or gentle conveying?

-

Are fillers, fibers, or recycled materials involved?

-

What level of dispersion and homogeneity is required?

For example, new materials and新能源-related compounds often require precise control of residence time and temperature to avoid degradation. In such cases, twin-screw extruders with modular screw elements are often more suitable than conventional single-screw designs.

Being (Shanghai) Intelligent Technology Co., Ltd. approaches extruder selection from a process-first perspective. By combining material analysis, process simulation, and engineering consulting, the company helps clients avoid mismatches between material behavior and equipment design, which is a common cause of unstable production and quality issues.

2. Output Capacity and Scalability

Production capacity is an obvious consideration, but it should not be evaluated in isolation.

Many manufacturers focus only on current output requirements, overlooking future expansion or product upgrades. Selecting an extruder that operates at the upper limit of its capacity from day one can lead to higher wear, reduced stability, and limited flexibility.

A more practical approach is to consider:

-

Stable operating range rather than maximum output

-

Ability to handle different formulations with minimal modification

-

Potential for future capacity expansion or line integration

In industries such as new energy materials and environmental protection, product specifications may evolve rapidly due to policy changes, technological breakthroughs, or market demand. An extruder system designed with scalability in mind can significantly reduce future retrofit costs.

As an integrated solution provider, Being (Shanghai) Intelligent Technology Co., Ltd. emphasizes system-level planning. Instead of supplying equipment in isolation, the company considers upstream feeding systems, downstream cooling and cutting, material handling, and digital control, ensuring that the extruder can scale smoothly within the entire production line.

3. Customization and Integration Capability

Standard extruder models can meet basic needs, but many modern manufacturing projects require customized solutions.

Customization may involve:

-

Special screw and barrel combinations

-

Customized feeding and dosing systems

-

Integration with material handling and conveying systems

-

Adaptation to cleanroom or environmentally controlled environments

-

Integration with digital manufacturing and MES systems

For example, in electronic materials or environmentally sensitive applications, strict control over contamination, dust, and emissions is essential. This requires not only customized extruder design but also coordinated integration with auxiliary equipment and environmental control systems.

Being (Shanghai) Intelligent Technology Co., Ltd. has strong advantages in this area. Beyond supplying industrial electromechanical equipment, the company provides engineering consulting, technical R&D support, and project management services. This allows extruder systems to be designed as part of a fully integrated intelligent manufacturing solution rather than as isolated machines.

To explore extruder solutions within an integrated engineering framework, you can refer to the following resource:

<a href="https://www.beyitech.com/Extruder">extruder system solutions</a>

4. Energy Efficiency and Sustainability

Energy consumption is no longer just an operating cost issue; it is a strategic consideration tied to carbon reduction goals and regulatory compliance.

Extruders are energy-intensive machines, and inefficient systems can significantly increase a factory’s carbon footprint. Key energy-related factors to evaluate include:

-

Drive system efficiency

-

Heating and cooling design

-

Screw and barrel efficiency in material conveying and melting

-

Intelligent control systems that optimize energy use under varying loads

For companies aiming to align with carbon neutrality or “zero-carbon” manufacturing goals, extruder selection should support energy monitoring, data analysis, and continuous optimization.

Being (Shanghai) Intelligent Technology Co., Ltd. positions sustainability as a core value rather than an afterthought. By integrating equipment, automation, and digital systems, the company helps clients reduce energy waste, improve process efficiency, and move toward carbon-neutral production. This approach is particularly relevant for new materials,新能源, and environmental protection industries, where sustainability is a core market requirement rather than a marketing slogan.

5. Reliability, Service Support, and Lifecycle Value

The final factor, often underestimated, is long-term reliability and service support.

An extruder is a long-term investment. Beyond initial installation, its performance over years of operation depends on:

-

Mechanical robustness and component quality

-

Ease of maintenance and spare parts availability

-

Technical support and troubleshooting capability

-

Upgrade and optimization potential over the equipment lifecycle

Frequent downtime, inconsistent output, or slow response to technical issues can quickly erase any short-term savings from lower initial equipment costs.

Being (Shanghai) Intelligent Technology Co., Ltd. provides value across the full project lifecycle. From early-stage consulting and system design to engineering construction, commissioning, and ongoing optimization, the company acts as a long-term partner rather than a one-time supplier. This lifecycle-oriented approach is especially important for complex integrated projects in intelligent manufacturing environments.

Conclusion

Choosing the right extruder is not about selecting a model from a catalog. It is about aligning material characteristics, production goals, system integration, sustainability objectives, and long-term operational stability into a coherent solution.

By focusing on material-process matching, scalable capacity, customization capability, energy efficiency, and lifecycle support, manufacturers can significantly reduce operational risks and improve overall competitiveness.

With its expertise in industrial equipment, engineering integration, and intelligent manufacturing solutions, Being (Shanghai) Intelligent Technology Co., Ltd. demonstrates how extruder selection can be elevated from a purchasing decision to a strategic component of sustainable, future-ready manufacturing.

www.beyitech.com

Being (Shanghai) Intelligent Technology Co., Ltd.