Custom Elevator Traction Systems: Meet Your Project Requirements

In the world of modern construction, elevators play a pivotal role in ensuring smooth vertical transportation within buildings. From residential complexes to commercial skyscrapers, the demand for efficient, safe, and reliable elevator systems has grown exponentially. Among these, custom elevator traction systems have emerged as the ideal solution for projects with unique specifications and performance requirements. In this article, we will explore how custom elevator traction systems can meet diverse project needs, the key factors to consider when designing or sourcing them, and why they are becoming the preferred choice for developers, engineers, and building owners worldwide.

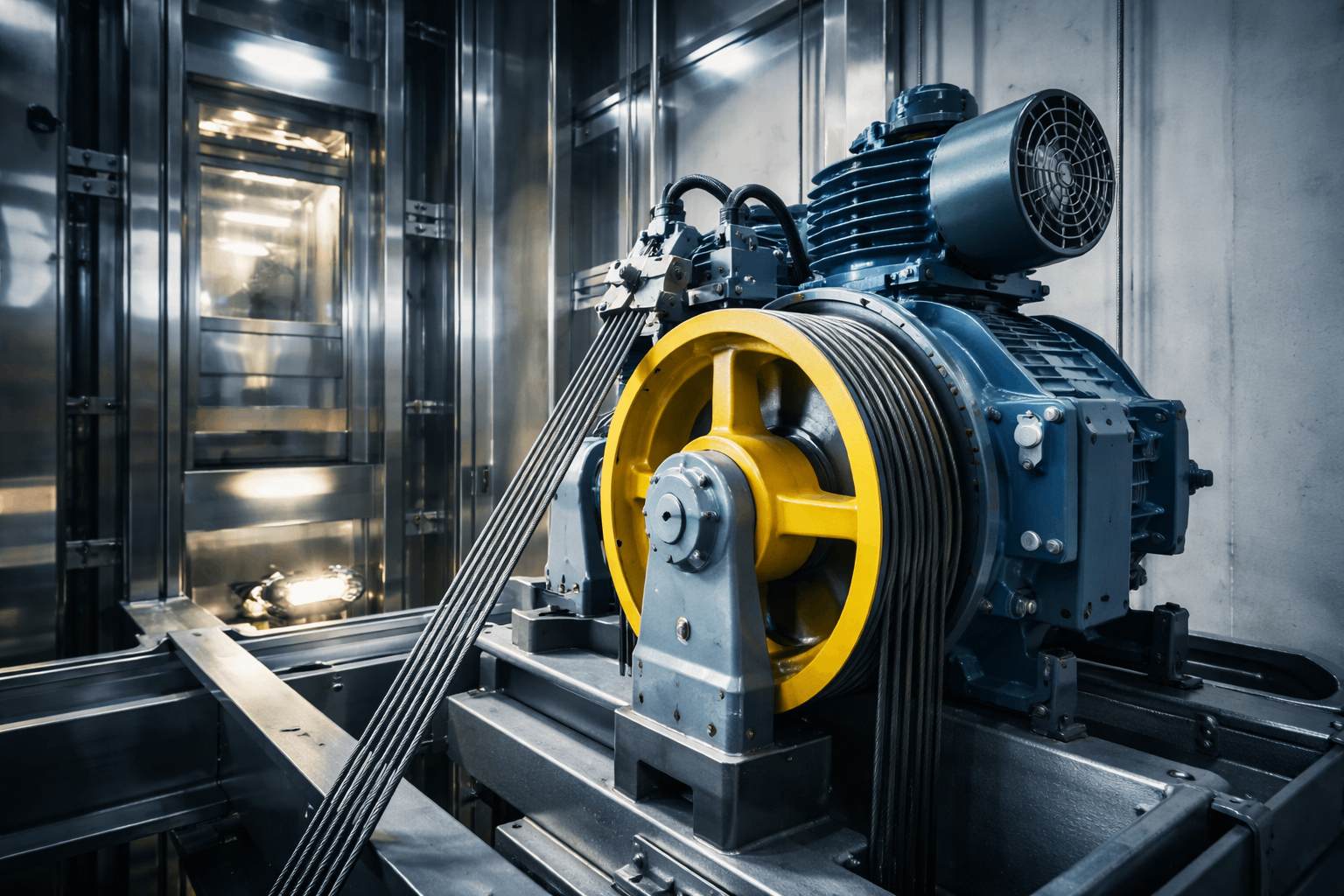

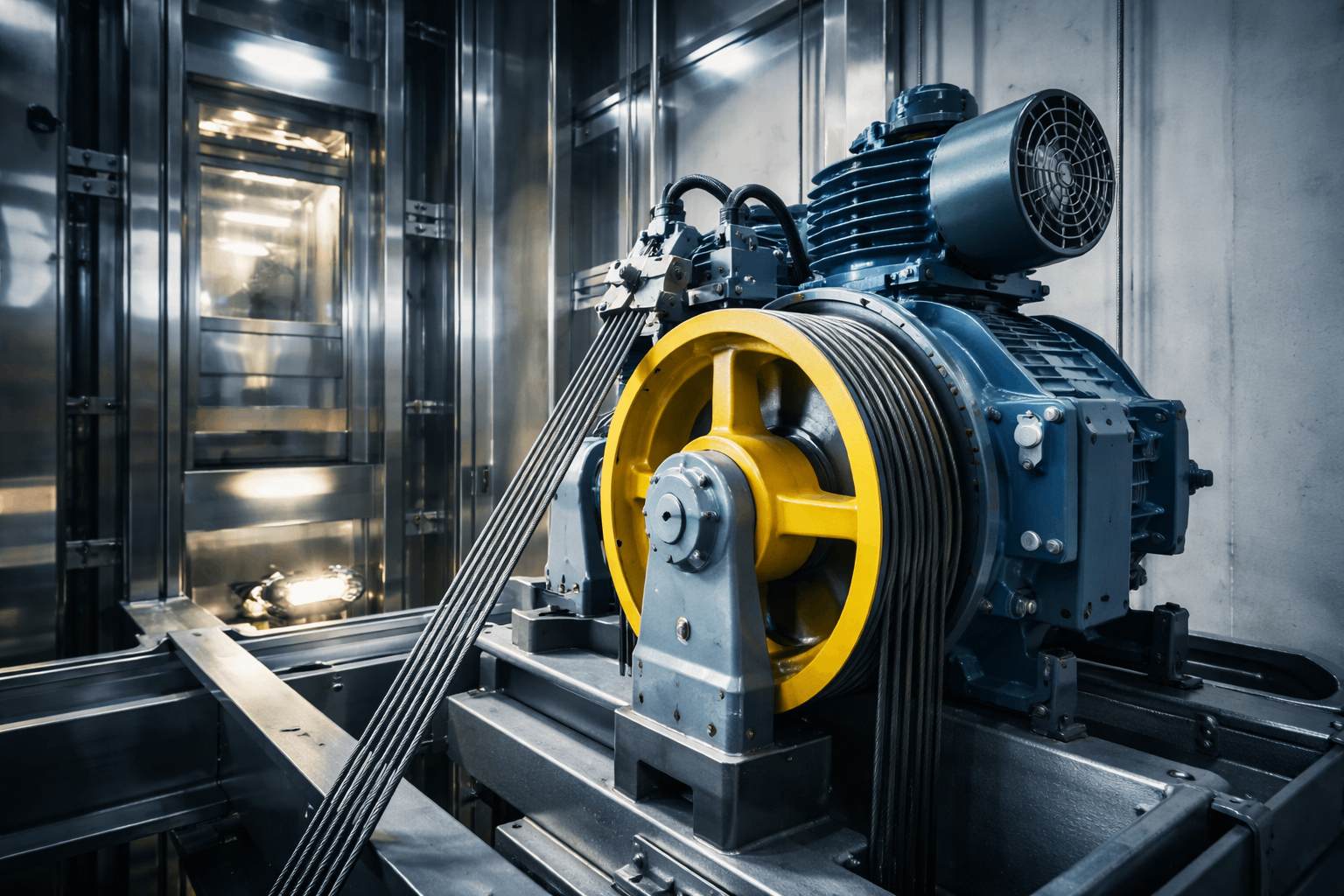

Understanding Elevator Traction Systems

Elevator traction systems are mechanical systems that move an elevator car using ropes or belts connected to a motor-driven pulley. Unlike hydraulic elevators, traction systems rely on counterweights and traction sheaves to achieve smooth, energy-efficient motion. These systems are highly favored for medium to high-rise buildings due to their speed, durability, and lower energy consumption.

The main components of an elevator traction system include:

-

Traction Motor: The core driving unit, responsible for moving the elevator car up and down. Motors can be geared or gearless, depending on the building height and performance requirements.

-

Traction Sheave: The pulley that guides the ropes and provides traction, ensuring the elevator moves smoothly.

-

Hoist Ropes: Strong steel cables or belts connecting the elevator car and counterweight to the traction sheave.

-

Counterweights: Used to balance the weight of the elevator car, reducing motor power requirements.

-

Control System: Advanced digital controls regulate acceleration, deceleration, and precise leveling of the elevator car.

While standard elevator traction systems work well for typical buildings, complex projects with unusual heights, heavy loads, or specific performance criteria often require custom solutions.

Why Choose Custom Elevator Traction Systems?

Custom elevator traction systems are designed to meet the unique requirements of a specific project, offering flexibility that off-the-shelf solutions cannot provide. Some key reasons to opt for a custom system include:

1. Project-Specific Design Requirements

Every building is unique. High-rise towers, luxury hotels, hospitals, and industrial facilities each have distinct elevator demands. Custom systems allow engineers to tailor motor capacity, speed, rope type, and control mechanisms to the building’s structural and operational requirements. For example, a 60-story skyscraper requires high-speed, gearless traction systems, while a mid-rise office building might function efficiently with a geared traction system.

2. Optimal Space Utilization

Building design often comes with space constraints in the elevator shaft or machine room. Custom traction systems can be engineered to fit into limited spaces without compromising performance. Compact motors, tailored counterweight configurations, and innovative pulley designs help maximize usable space while maintaining efficiency.

3. Enhanced Energy Efficiency

Energy consumption is a major concern for modern construction. Custom traction systems can be optimized for regenerative drives, lightweight materials, and energy-saving motors. These enhancements not only reduce operational costs but also align with green building certifications, such as LEED and BREEAM.

4. Superior Passenger Experience

Custom systems can be designed to minimize noise, vibration, and jerk during elevator movement. Smooth acceleration and deceleration profiles, advanced suspension systems, and precision leveling contribute to a more comfortable ride, which is particularly important in luxury or high-traffic buildings.

5. Safety and Compliance

High-rise buildings require elevators that meet stringent safety standards. Custom traction systems can integrate redundant braking systems, emergency lowering mechanisms, and advanced monitoring technologies to comply with international safety regulations such as EN 81-20/50, ASME A17.1, and ISO standards.

Key Considerations When Designing Custom Elevator Traction Systems

When planning a custom elevator traction system, several factors must be carefully considered to ensure optimal performance and reliability.

1. Building Height and Load Requirements

The height of the building and the intended passenger or freight load determine the type of traction system, motor power, and rope specifications. Gearless traction systems are ideal for high-rise structures due to their high speed and efficiency, while geared systems may be sufficient for mid-rise buildings.

2. Speed and Performance

Custom systems allow designers to set target speeds based on the building’s usage patterns. High-speed elevators (up to 10 m/s or more) are common in skyscrapers, while slower speeds suffice for residential or low-rise commercial buildings. Acceleration and deceleration profiles can also be customized to reduce wear on mechanical components and enhance passenger comfort.

3. Shaft and Machine Room Constraints

The physical layout of the building often dictates the size and configuration of the elevator system. Custom solutions can incorporate compact motors, variable frequency drives, and innovative counterweight arrangements to fit the available space while maintaining efficiency.

4. Control System and Smart Integration

Modern custom traction systems integrate digital control systems capable of advanced scheduling, energy management, and predictive maintenance. For large buildings with multiple elevators, group control systems optimize traffic flow, reduce waiting times, and improve energy efficiency.

5. Material Selection and Durability

Ropes, pulleys, motors, and car frames must be selected based on environmental conditions, load cycles, and expected lifespan. High-strength ropes, corrosion-resistant components, and durable motor systems extend the service life of the elevator while minimizing maintenance costs.

Advantages of Working With Experienced Manufacturers

Partnering with a professional elevator traction system manufacturer is critical for successful custom solutions. Experienced manufacturers provide:

-

Design Expertise: Ability to engineer systems that meet specific project needs.

-

Quality Assurance: Compliance with international standards and rigorous testing procedures.

-

Project Support: Assistance with installation, commissioning, and after-sales maintenance.

-

Global Supply Chain: Reliable sourcing of high-quality materials and components.

By collaborating with a reputable supplier, building owners and contractors can ensure that their custom elevator systems are delivered on time, perform reliably, and adhere to safety regulations.

Case Study: Custom Elevator Traction System for a Skyscraper

Consider a 75-story commercial skyscraper with high passenger traffic. The project required:

-

Gearless traction motors for high-speed travel up to 10 m/s.

-

Regenerative drives for energy recovery.

-

Compact counterweight system to fit a limited machine room.

-

Advanced digital control system for group elevator management.

By commissioning a custom elevator traction system, the project team achieved:

-

Reduced energy consumption by 25% compared to standard systems.

-

Smooth ride experience with minimal vibration.

-

Compliance with all international safety standards.

-

Efficient use of limited machine room space.

This case demonstrates how custom solutions can precisely meet complex project requirements, enhancing both performance and operational efficiency.

Conclusion

Custom elevator traction systems offer unparalleled flexibility, efficiency, and performance for buildings with unique vertical transportation needs. By tailoring motor power, speed, control systems, and mechanical components to project specifications, developers can achieve energy savings, superior passenger comfort, and long-term reliability.

When choosing a custom elevator traction system, it is essential to work with experienced manufacturers who understand the nuances of design, installation, and maintenance. With proper planning and collaboration, a custom solution not only meets project requirements but also provides a competitive advantage in building efficiency and occupant satisfaction.

For developers, engineers, and building owners seeking reliable, high-performance elevators, investing in a custom elevator traction system is a strategic decision that delivers both operational excellence and peace of mind.

www.xinlinelevator.com

xinlinelevator