How Glass Sealed Crystals Enhance Device Stability

In the modern electronics industry, stability and precision are critical factors for any device, especially those that rely on accurate timing and frequency control. One of the most effective methods to achieve high stability in electronic components is through the use of glass sealed crystals. Companies like LUCKI ELECTRONIC (LUCKI®) have leveraged decades of experience in crystal and oscillator technology to develop products that meet the highest standards for reliability across a range of applications.

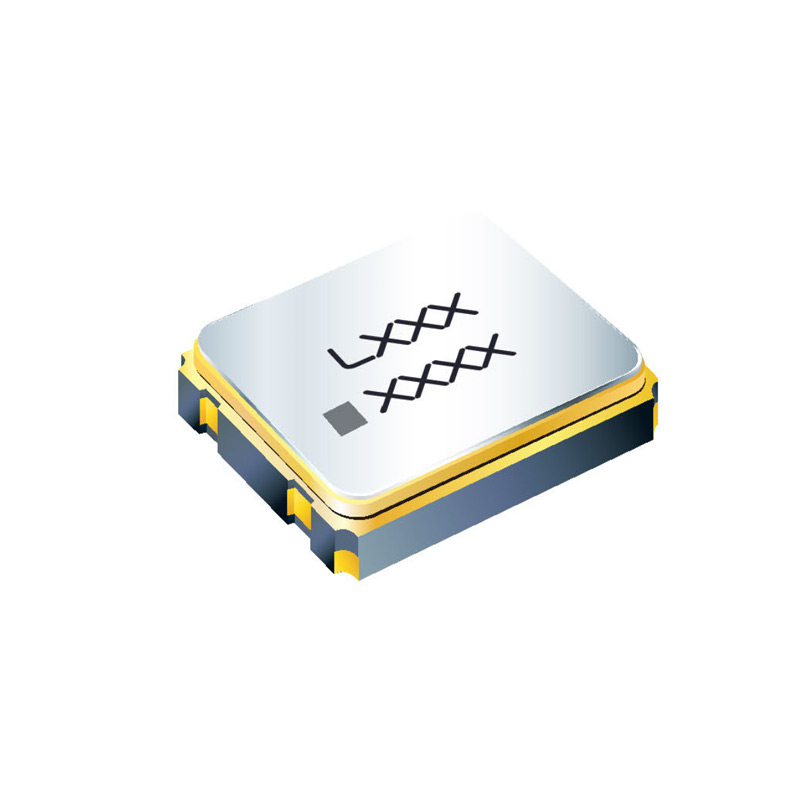

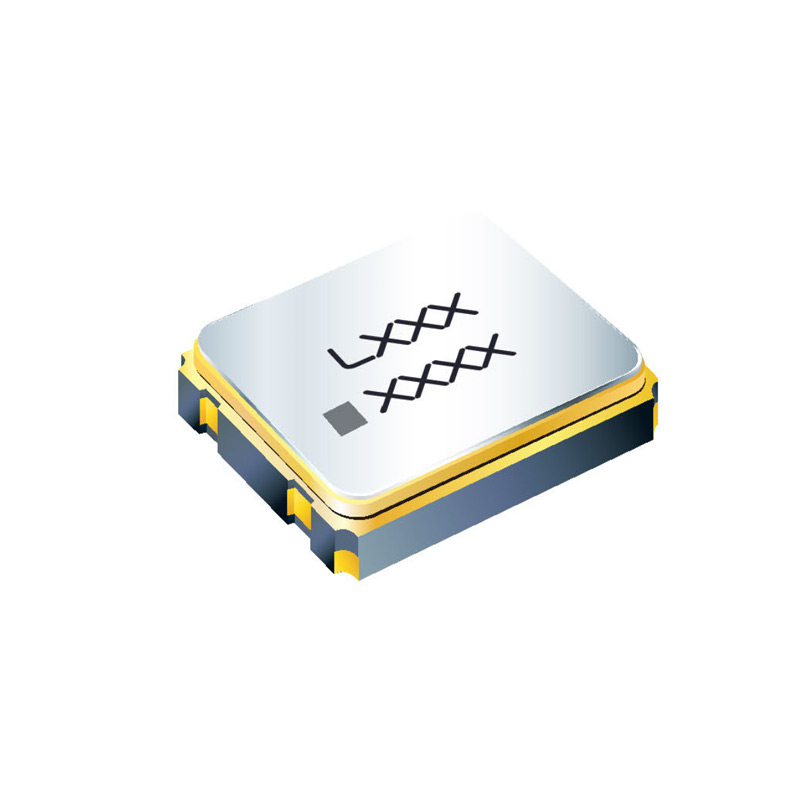

Glass sealed crystals are a type of quartz crystal oscillator in which the quartz element is hermetically sealed inside a glass enclosure. This design protects the crystal from external environmental factors, such as humidity, dust, and mechanical stress, all of which can significantly degrade the performance of electronic devices over time. By isolating the crystal from these variables, glass sealing ensures that the oscillator maintains a consistent frequency, improving the overall stability and lifespan of the device.

LUCKI ELECTRONIC (LUCKI®) has been a pioneer in this field, producing high-precision frequency products, quartz crystals, oscillators, and ceramic resonators. With a comprehensive range of SMD and through-hole crystal oscillator products—including VCXO, TCXO, and OCXO—LUCKI® caters to a broad spectrum of industries. These products are widely used in satellite navigation, base stations, data servers, cloud platforms, artificial intelligence systems, autonomous driving, smart home devices, medical equipment, smart cities, industrial control, renewable energy, and consumer electronics.

One of the key advantages of glass sealed crystals is their superior thermal stability. Temperature fluctuations can cause significant frequency drift in conventional crystal oscillators. However, the hermetic sealing and high-quality quartz material used in glass sealed crystals minimize this drift. This characteristic is particularly important in mission-critical applications such as satellite navigation systems and telecommunications infrastructure, where even minor timing errors can lead to significant operational problems.

Another benefit of glass sealed crystals is their enhanced mechanical resilience. Devices in industrial and automotive environments often encounter vibrations, shocks, and pressure variations. A crystal oscillator exposed to such conditions without proper protection can suffer from frequency shifts or complete failure. The glass enclosure acts as a buffer, absorbing external mechanical stress and maintaining the oscillator’s integrity. LUCKI®’s products are designed to meet rigorous mechanical standards, ensuring reliable performance in harsh operating conditions.

The manufacturing process of glass sealed crystals also contributes to their stability. The sealing process involves placing the quartz crystal in a precisely controlled environment before hermetically sealing it within a glass envelope. This prevents contamination and ensures a vacuum or inert atmosphere around the crystal. Over decades of refinement, LUCKI® has optimized this process to achieve consistent quality and performance, allowing them to deliver billions of timing and magnetic solutions to customers in over 50 countries and regions.

Electrical performance is another area where glass sealed crystals excel. Reduced contamination and environmental influence mean lower aging rates and minimal frequency drift. For applications requiring long-term stability—such as cloud data servers, AI computing nodes, and autonomous vehicles—these characteristics are critical. LUCKI®’s TCXO (Temperature Compensated Crystal Oscillator) and OCXO (Oven Controlled Crystal Oscillator) products provide engineers with the precision and reliability needed for complex systems that demand uninterrupted operation.

A practical example of the importance of glass sealed crystals can be found in medical devices. In equipment like MRI machines or precision diagnostic instruments, timing accuracy directly impacts measurement reliability. Even slight frequency deviations can compromise the accuracy of results. By employing glass sealed crystals, manufacturers can ensure that their devices maintain precise timing, enhancing both safety and performance.

In smart city infrastructure and industrial IoT applications, the role of crystal stability cannot be overstated. Sensor networks, communication nodes, and automation systems depend on synchronized timing. Any drift in oscillator frequency can propagate errors across the network, leading to inefficiency or malfunction. The long-term stability of glass sealed crystals allows engineers to design robust systems capable of reliable operation over years, even in challenging environments.

LUCKI ELECTRONIC (LUCKI®) supports these applications through a combination of advanced manufacturing techniques and comprehensive product development. Their experience in both SMD and through-hole crystal oscillator technologies ensures that customers can find suitable solutions for both compact electronics and high-reliability industrial devices. Their product portfolio covers a wide frequency range and includes options optimized for low power consumption, high stability, and minimal phase noise.

For engineers and designers seeking reliable components, understanding the advantages of glass sealed crystals is essential. Not only do these devices offer superior environmental protection and mechanical resilience, but they also deliver long-term frequency accuracy that is vital for the success of complex electronic systems. By choosing products from a trusted manufacturer like LUCKI ELECTRONIC (LUCKI®), engineers gain access to decades of expertise and a track record of delivering over 10 billion passive and active timing and magnetic solutions globally.

To explore LUCKI®’s full range of quartz crystal products and learn more about their specifications, performance characteristics, and applications, visit Glass Sealed Crystal.

In conclusion, glass sealed crystals represent a critical component for enhancing the stability, reliability, and lifespan of electronic devices. Their superior thermal performance, mechanical resilience, and precise manufacturing make them indispensable for applications spanning telecommunications, autonomous systems, medical devices, smart infrastructure, and industrial control. With leaders like LUCKI ELECTRONIC (LUCKI®) pushing the boundaries of crystal technology, engineers have access to components that not only meet but exceed the demanding requirements of modern electronic systems.

www.cnlucki.com

LUCKI ELECTRONIC(LUCKI®)