How to Choose the Right Anodized Aluminum Profiles for Architectural Projects

1. Introduction

Choosing the right anodized aluminum profiles is essential for any architectural project—impacting durability, aesthetics, and performance. In this guide, we'll show how to choose the right anodized aluminum profiles for architectural projects, highlighting key factors and explaining why Jiangxi KaiMeiDa aluminum—the largest aluminum profile production base in Jiangxi Province—is an excellent option.

2. Understand Project Needs First

Start by defining your project’s requirements: load-bearing capacity, environmental exposure (coastal, industrial, UV), and design requirements. For example, curtain walls require strong, corrosion-resistant profiles, while interior trim may prioritize finish and color.

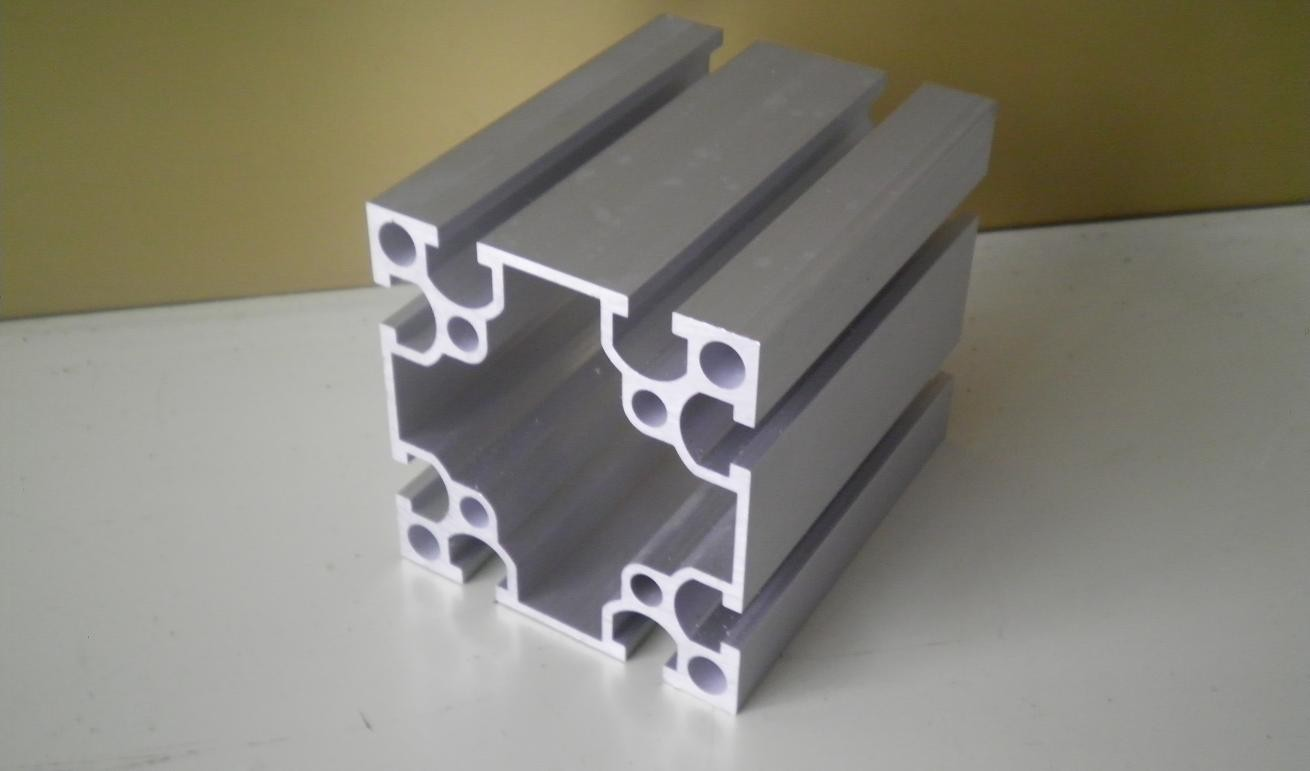

3. Material Quality: Alloy & Temper

Anodized aluminum profiles begin with high-purity alloys like 6063-T5 (often used in construction). Look for ISO 9001–certified profiles, which Jiangxi KaiMeiDa provides, ensuring consistent alloy composition and mechanical strength.

4. Surface Treatment: Thickness & Appearance

Anodization enhances corrosion resistance and aesthetics. Architectural projects typically require anodic layers ≥ 15 μm for exterior use, offering long-lasting finish. KaiMeiDa provides diverse anodizing finishes—clear, espresso, bronze, black pearl, sandstone—with tight color consistency for large-scale builds .

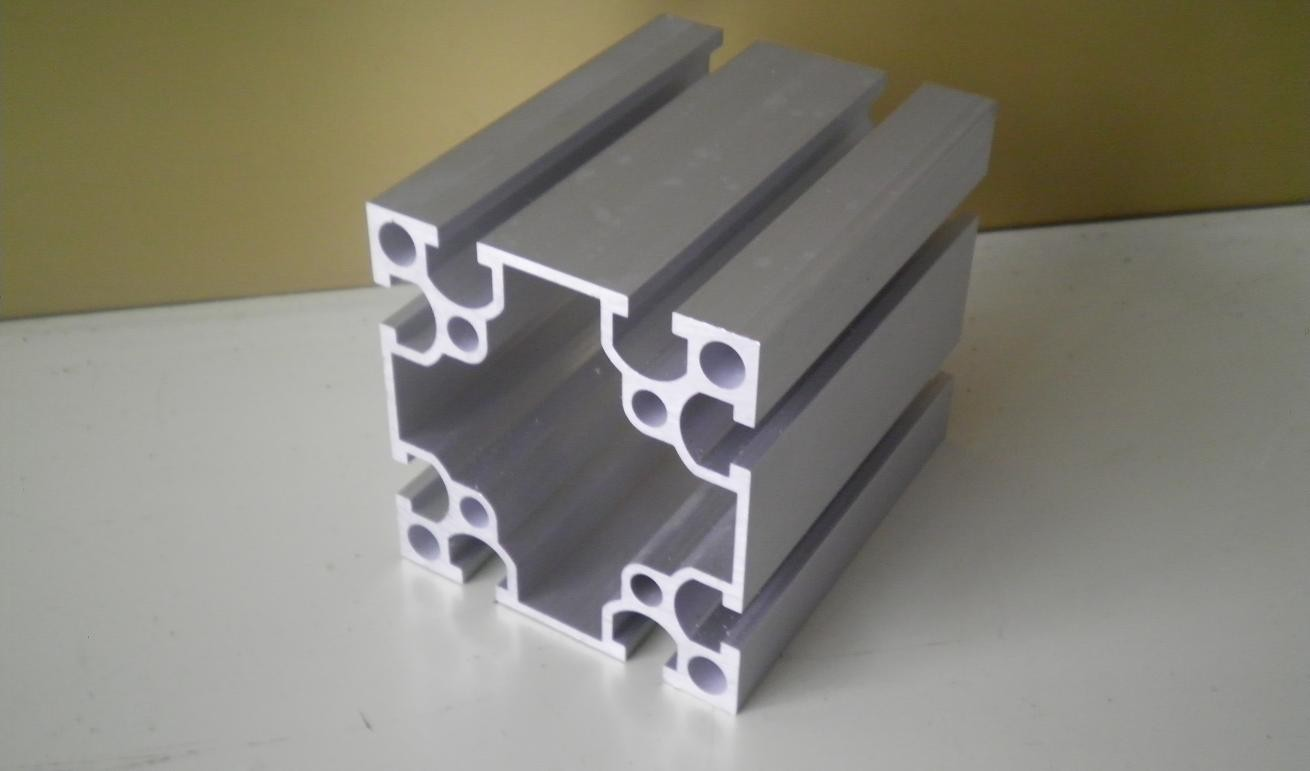

5. Dimensional Precision Matters

Architectural assemblies rely on precise dimensions and tight tolerances. Ensure your supplier has multiple extrusion lines and stringent QC. KaiMeiDa operates over 10 advanced extrusion lines and modern QC labs with Japan/Germany equipment .

6. Structural Performance & Certification

For structural elements like framing or mullions, profiles must meet bending and load standards. KaiMeiDa’s products adhere to national standard GB 5237-2000 and carry ISO 9001 and CQM/ISO 14001 certifications—signaling both dimensional and environmental compliance.

7. Customization & Production Scale

Large architectural projects often need customized profiles. With a 60,000 m² plant and annual output over 30,000 t, KaiMeiDa can handle high-volume custom orders, incorporating specific cross-sections, alloy grades, and finishes—included via OEM/ODM support.

8. Logistics & Lead Times

Manufacturing capacity matters, but so does supply stability. KaiMeiDa’s 120-mu facility in Nanchang has good transport links—20 min from the airport, near a major highway—ensuring steady delivery. Their usual lead times range from 1 month (off-season) to 1–3 months in peak periods.

9. Environmental & After-Sales Considerations

Sustainable materials matter more than ever. KaiMeiDa holds ISO 14001 environmental certification, reflecting its commitment to eco-friendly production. Also, verify if warranties, replacement parts, and technical service are available—critical for long-term projects.

10. Cost vs Value: Make a Smart Choice

While initial price is important, consider lifetime value. High-quality anodized profiles from a reputable manufacturer reduce maintenance, repainting, and replacements. KaiMeiDa’s certified, precision-made profiles offer strong ROI, balancing cost and performance.

11. Conclusion

By following these steps—evaluating material quality, finish durability, dimensional accuracy, certifications, customization capability, logistics, and eco credentials—you’ll succeed in choosing the right anodized aluminum profiles for architectural projects. Jiangxi KaiMeiDa aluminum, boasting Jiangxi’s largest extrusion facility, ISO‑9001 quality, ISO‑14001 environmental certifications, and strong customization capacity, is a reliable choice for architects and engineers. Investing in properly specified anodized profiles today ensures your project looks great and stands strong for years to come.

www.jxkmdly.com

Jiangxi KaiMeiDa aluminum