How to extend the service life of welding hydraulic cylinder?

As a crucial actuator in the hydraulic system, the welded hydraulic cylinder is widely used in engineering machinery, mining equipment, agricultural machinery, metallurgical equipment and other industries. With the advantages of compact structure, high strength and easy installation, it still performs well in harsh working environments. However, when the hydraulic cylinder works under high frequency, high load and complex environment, it is also prone to wear, leakage, damage and other problems, which seriously affect the operating efficiency of the equipment and even cause safety accidents. Therefore, mastering the correct use method and maintenance skills is crucial to extend the service life of the welded hydraulic cylinder.

This article will analyze in detail from multiple aspects such as selection, installation, use and maintenance to help users scientifically and effectively extend the service life of the welded hydraulic cylinder.

1. Choose high-quality welded hydraulic cylinders

The first step to extend the life of the hydraulic cylinder is to control the quality from the source.

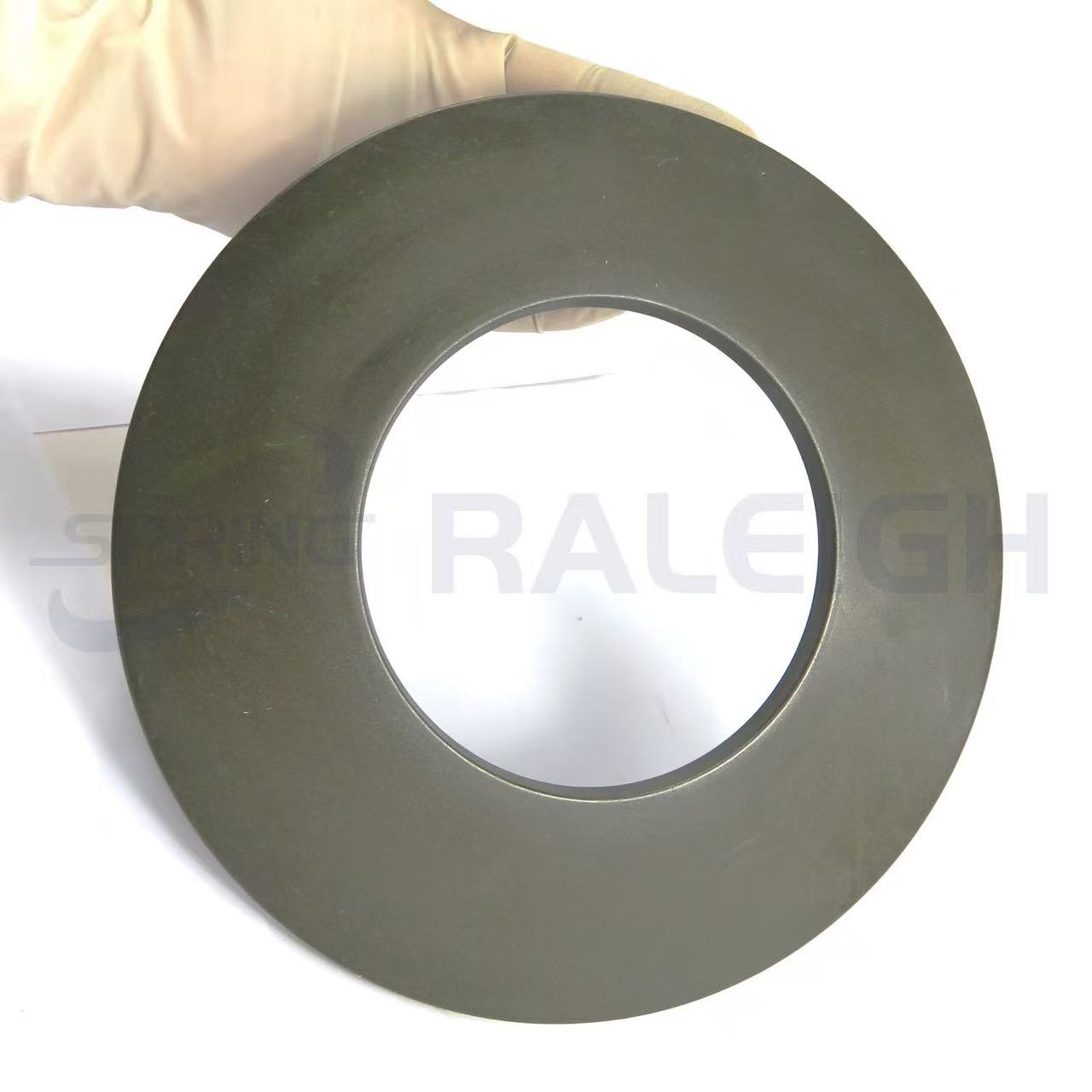

Select high-quality materials: high-quality welded hydraulic cylinders usually use high-strength steel, and the materials such as cylinder barrels, piston rods, and seals have excellent performance and can withstand high pressure and impact.

High processing precision: The roughness, roundness, coaxiality, etc. of the inner wall of the cylinder barrel directly affect the sealing and friction of the hydraulic cylinder. High-precision processing can reduce wear and leakage.

Reasonable structural design: Select appropriate cylinder diameter, stroke, buffer structure and sealing structure according to the application environment, so that it can meet the work needs and avoid over-design or overload operation.

If the budget allows, it is recommended to choose an experienced and reputable brand or supplier to customize the welded hydraulic cylinder, and put forward customized requirements according to the actual working conditions.

2. Standardize installation to avoid hidden dangers

Even if the hydraulic cylinder itself is of reliable quality, if it is improperly installed, it will greatly shorten its service life.

Ensure the correct installation position: Welded hydraulic cylinders are usually connected by pins. During installation, the coaxiality and verticality of the connections at both ends should be ensured to avoid eccentric force.

Avoid excessive lateral force: The hydraulic cylinder is designed to withstand axial force. If there is a large lateral force or bending moment during work, the piston rod will bend, the seal will be worn or even broken.

Provide good support and guidance: Long-stroke hydraulic cylinders should have suitable support and guide structures in the middle and at the end of the piston rod to avoid vibration and sagging.

Check the hydraulic pipeline connection: The hydraulic oil pipe connection must be firm and leak-free to avoid damage caused by unstable pressure or foreign matter entering.

3. Correct operation and avoid overload

During the use of welding hydraulic cylinders, operating habits have a great impact on their life.

Avoid overload work: It is strictly forbidden for hydraulic cylinders to work for a long time under load and pressure exceeding the rated value, otherwise it is easy to cause cylinder expansion and cracking, piston rod bending and even failure.

Avoid high-frequency reverse impact: Frequent rapid reverse movement will aggravate the fatigue of internal parts, and high-frequency start, stop and direction switching should be avoided.

Control the working environment temperature: High temperature will accelerate the aging of seals, and low temperature may cause the viscosity of hydraulic oil to be too high. Try to keep working within the temperature range allowed by the hydraulic cylinder design.

Keep the hydraulic oil clean: Impurities mixed in the hydraulic oil will wear the cylinder and seals. The hydraulic oil must be checked and replaced regularly to ensure the cleanliness of the oil.

4. Regular maintenance and care

Welding hydraulic cylinders are consumable parts and require regular maintenance to maintain their optimal working condition.

Check fasteners: Regularly check whether the fastening bolts and pins are loose, and tighten them in time.

Check the seal: The seal is a key component of the hydraulic cylinder. It is easy to age, wear and deform. It needs to be checked regularly for leaks and cracks and replaced in time.

Check the surface of the piston rod: The surface of the piston rod should be smooth without scratches or rust. If there is any damage, it should be repaired or replaced in time.

Lubrication and rust prevention: The exposed piston rod should be regularly coated with anti-rust oil or lubricating oil to avoid rust and wear.

Check the quality of hydraulic oil: If the hydraulic oil is deteriorated or contaminated, it should be replaced in time, and the filter element should also be replaced regularly.

Regularly bleed: If air is mixed into the hydraulic system, it will affect the working stability and aggravate the impact. It needs to be vented regularly.

5. Reasonable storage of spare hydraulic cylinders

Many users will purchase spare welding hydraulic cylinders in advance, but the wrong storage method will also lead to a decrease in their performance.

Before storage, the piston rod of the hydraulic cylinder should be retracted into the cylinder to prevent dust and water vapor from contacting the surface of the piston rod.

The storage environment should be dry, ventilated, moisture-proof and corrosion-resistant.

Apply anti-rust oil to the exposed part and wrap it with a protective cover.

Regularly check the status of the hydraulic cylinders in stock to avoid long-term idleness leading to adhesion of internal parts or aging of seals.

6. Measures for special working conditions

In some special or harsh working conditions, such as high temperature, high dust, corrosive environment, offshore operations, etc., higher requirements are placed on welding hydraulic cylinders.

High temperature environment: Select high temperature resistant seals and high temperature hydraulic oil, and appropriately reduce the workload.

Dust environment: Install dust rings and sleeves, and regularly clean external dust.

Corrosive environment: Select corrosion-resistant coating or stainless steel piston rod, and spray anti-corrosion paint on the surface.

Underwater environment: Use special sealing structure and waterproof coating.

As an important power component in the hydraulic system, welding hydraulic cylinders are related to the stability and efficiency of the entire equipment. Selecting high-quality products, scientific and reasonable installation, standardized operation, regular maintenance and taking special measures according to working conditions are the key to extending the service life of welding hydraulic cylinders.

For users, extending the life of hydraulic cylinders can not only reduce equipment downtime and maintenance costs, but also improve production efficiency and ensure work safety. Therefore, enterprises and operators should establish a correct awareness of use and maintenance, start from the details, give full play to the performance advantages of welding hydraulic cylinders, and escort production.

As a professional welding hydraulic cylinder factory, we are well aware of the importance of product quality and service life to customers. With many years of manufacturing experience, we use high-quality steel and high-precision processing technology to ensure that each hydraulic cylinder has high strength, good sealing, durability and reliability. At the same time, we also provide customers with full support such as selection guidance, installation suggestions, and maintenance plans to help customers use scientifically and maintain regularly, maximize the service life of hydraulic cylinders, reduce maintenance costs, and improve production efficiency. Choosing us means choosing stability and security!

www.toringcylinder.com

toringcylinder