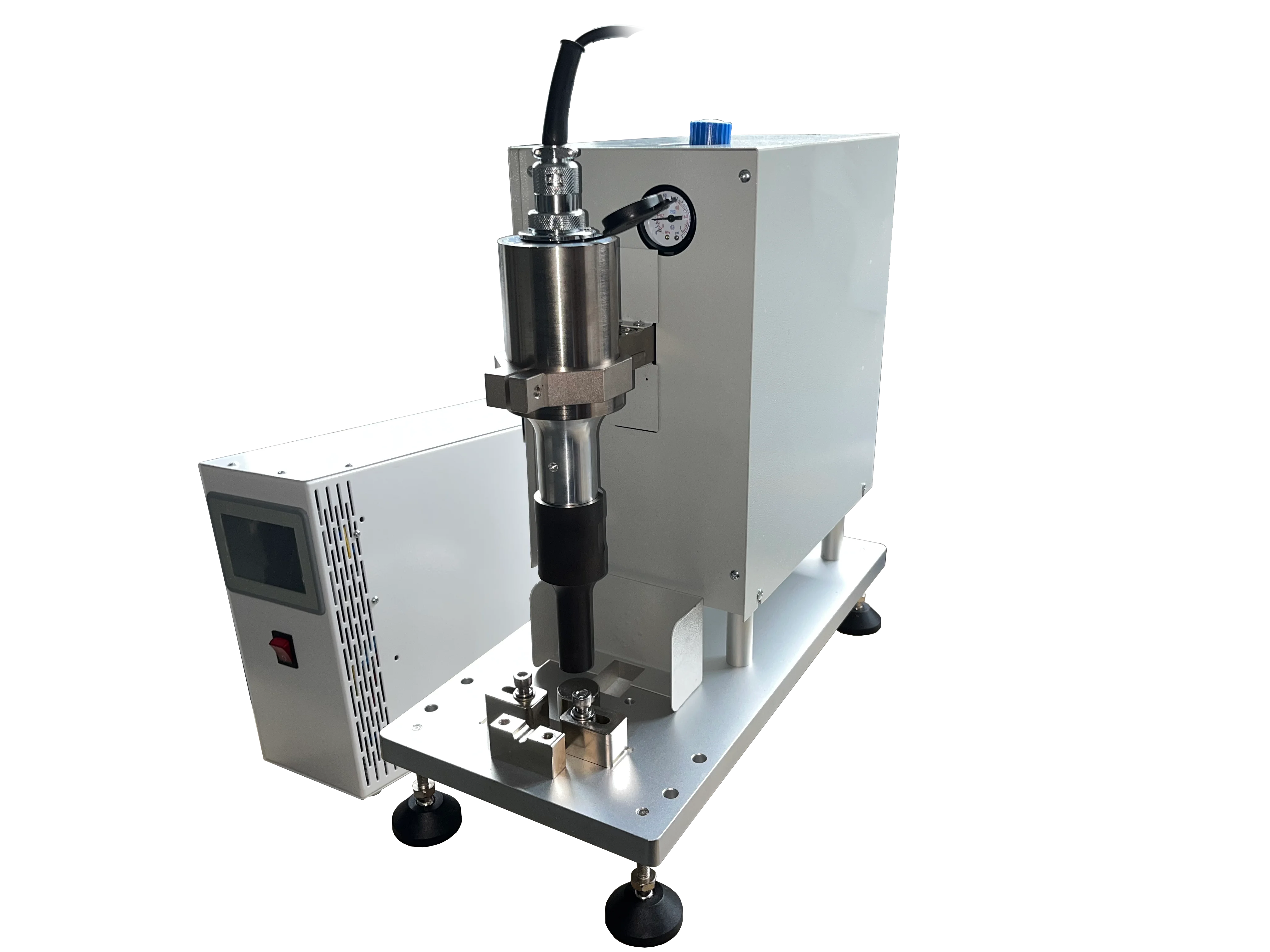

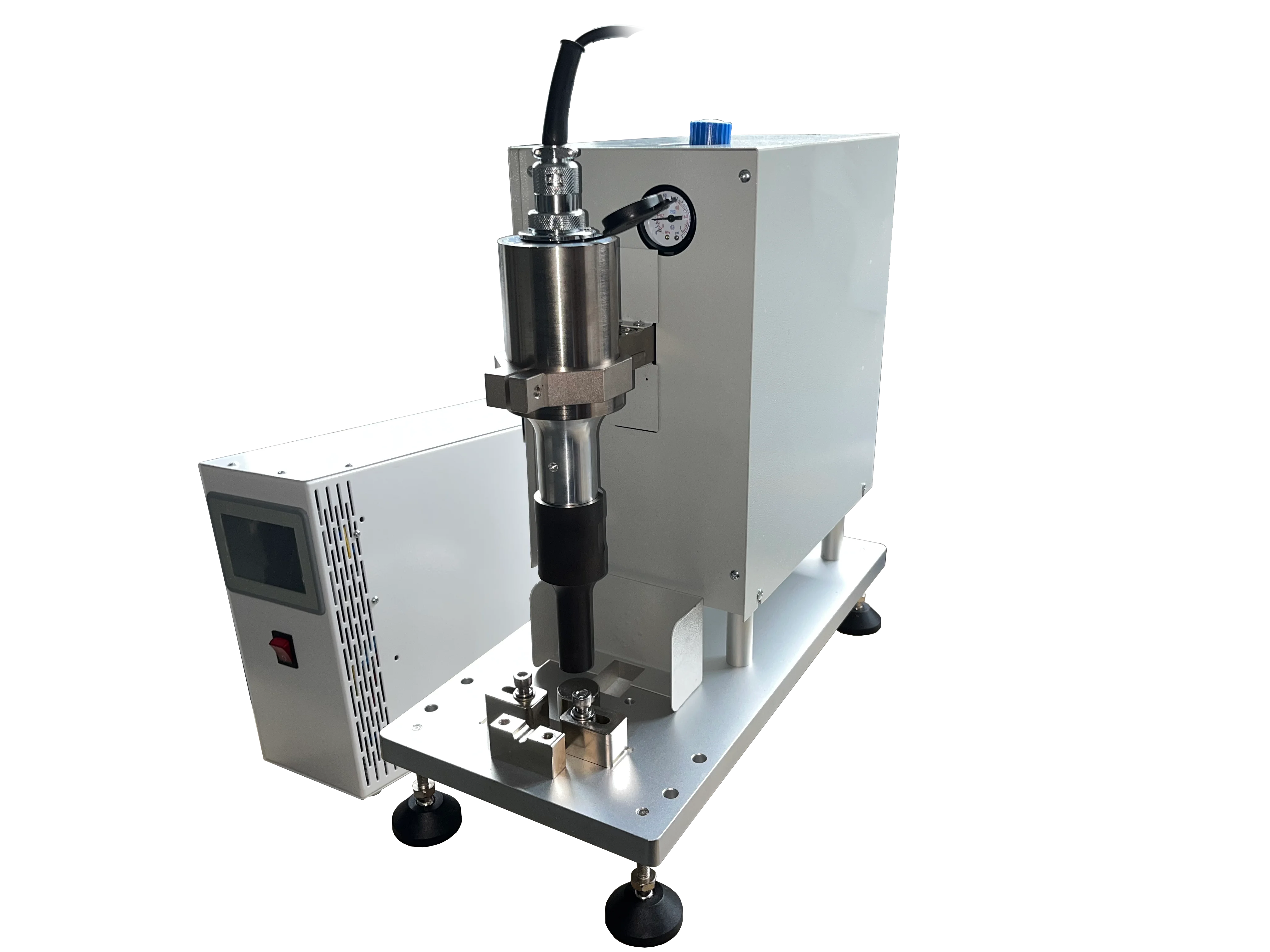

Learn how the Industrial Ultrasonic MI Cable Stripping Machine Works

In modern industrial applications, Mineral-Insulated (MI) cables play a crucial role in environments that demand high-performance electrical wiring with exceptional durability. These cables are widely used in industries such as aerospace, nuclear power, petrochemicals, and fire protection systems. However, processing MI cables requires specialized techniques due to their rugged construction.

One of the most advanced and efficient methods for preparing MI cables is through the use of an Industrial Ultrasonic MI Cable Stripping Machine. This technology leverages ultrasonic energy to strip MI cables cleanly and precisely, offering significant advantages over traditional mechanical or chemical stripping methods.

In this article, we will explore how the Industrial Ultrasonic MI Cable Stripping Machine works, its key components, advantages, and applications in various industries.

Understanding MI Cables and the Need for Ultrasonic Stripping

What Are Mineral-Insulated (MI) Cables?

Mineral-Insulated (MI) cables are designed for high-temperature and high-stress applications. They consist of:

A metal sheath (typically copper or stainless steel): This provides protection against external environmental factors such as heat, moisture, and chemicals.

Magnesium oxide (MgO) insulation: An inorganic compound that acts as a fire-resistant insulator.

Conductors (copper or nickel alloy): These are embedded within the MgO insulation to carry electrical current.

Due to the robust and compact nature of MI cables, traditional stripping methods such as mechanical cutting or chemical stripping may not be ideal. These methods can cause:

Damage to internal conductors

Irregular stripping results

Increased material waste

Longer processing times

The Role of Ultrasonic Technology in Cable Stripping

Ultrasonic stripping utilizes high-frequency vibrations to break down the bonds between the sheath and insulation. Unlike mechanical methods that rely on physical force, ultrasonic energy ensures a clean and precise removal of the sheath without damaging the internal conductors.

How the Industrial Ultrasonic MI Cable Stripping Machine Works

1. Ultrasonic Energy Generation

The process begins with the ultrasonic generator, which converts electrical energy into high-frequency mechanical vibrations. These vibrations typically operate at frequencies between 20 kHz and 40 kHz, depending on the specific stripping requirements.

2. Transducer and Horn Mechanism

The generated ultrasonic waves are transmitted to a piezoelectric transducer, which amplifies and converts the energy into mechanical motion. This motion is further intensified by the horn (sonotrode), which focuses the vibrations onto the MI cable's sheath.

3. Sheath Separation via High-Frequency Vibrations

As the horn makes contact with the MI cable’s sheath, the ultrasonic vibrations create microscopic pressure waves. These waves:

Disrupt the molecular bonds between the sheath and the magnesium oxide insulation

Cause the sheath material to weaken and crack without damaging the underlying insulation

Result in a clean and efficient stripping process without the need for excessive force or external chemicals

4. Precision Control and Automation

Modern ultrasonic MI cable stripping machines feature precision control mechanisms, including:

Adjustable vibration frequency and amplitude for different cable diameters

Programmable stripping lengths to accommodate varying cable specifications

Automated feeding systems for high-volume industrial production

These features ensure that each stripped MI cable meets stringent industry standards with minimal errors.

Advantages of Using an Industrial Ultrasonic MI Cable Stripping Machine

1. Precision and Consistency

Ultrasonic stripping allows for highly accurate sheath removal without affecting the insulation or conductors.

It ensures consistent results across large batches, reducing defects and material waste.

2. Non-Destructive Process

Unlike mechanical cutting, ultrasonic stripping does not cause nicks, cuts, or abrasions on the conductors.

This enhances the reliability and longevity of the cables in demanding industrial environments.

3. Increased Efficiency and Speed

The ultrasonic method is significantly faster than manual or traditional stripping methods.

It enables mass production with high throughput, making it ideal for industries requiring large-scale MI cable processing.

4. Enhanced Safety and Environmental Benefits

The process eliminates the need for hazardous chemicals used in chemical stripping.

It reduces dust and debris compared to mechanical stripping, improving workplace safety.

5. Lower Maintenance and Operating Costs

Ultrasonic machines have fewer moving parts, leading to reduced maintenance requirements.

The non-contact nature of ultrasonic stripping extends the lifespan of the equipment, reducing downtime and repair costs.

Applications of Ultrasonic MI Cable Stripping Machines

1. Aerospace Industry

MI cables are extensively used in aircraft and spacecraft for their fire-resistant properties.

Ultrasonic stripping ensures precise and reliable cable preparation for critical aerospace applications.

2. Nuclear and Power Generation

In nuclear power plants, MI cables provide safety-critical wiring in extreme conditions.

Ultrasonic stripping guarantees damage-free preparation of these essential cables.

3. Petrochemical and Industrial Automation

MI cables are used in refineries and industrial automation systems for high-temperature resistance.

Ultrasonic stripping facilitates fast and accurate processing of cables for installation and maintenance.

4. Fire Protection Systems

MI cables are an integral part of fire-resistant wiring in buildings and tunnels.

The ultrasonic stripping process ensures reliable and high-quality cable terminations for fire safety applications.

Conclusion

The Industrial Ultrasonic MI Cable Stripping Machine is a game-changer in the world of high-performance cable processing. By leveraging high-frequency ultrasonic vibrations, this technology ensures precision, efficiency, and safety, making it the preferred choice for industries that rely on MI cables.

With the increasing demand for durable and reliable electrical wiring, ultrasonic stripping machines are set to become a standard tool in modern cable processing facilities. As advancements continue, we can expect even greater levels of automation and innovation in this essential industrial technology.

Hangzhou Successful Ultrasound Equipment Co., Ltd. is a domestic professional manufacturer engaged in ultrasonic application research, development and production of high-power ultrasonic transducers, and is a national high-tech enterprise. The company's main products include transducers, ultrasonic drive power supplies, etc. As the core and key components of power supplies, these products are widely used in sonochemistry, plastic welding, metal welding, rubber cutting, non-woven fabric welding and other ultrasonic application industries.

If you are interested in our Industrial Ultrasonic MI Cable Stripping Machine , please contact us. We will provide you with Industrial Ultrasonic MI Cable Stripping Machine solutions.

www.hzcgultrasonic.com

Hangzhou Successful Ultrasound Equipment Co., Ltd.