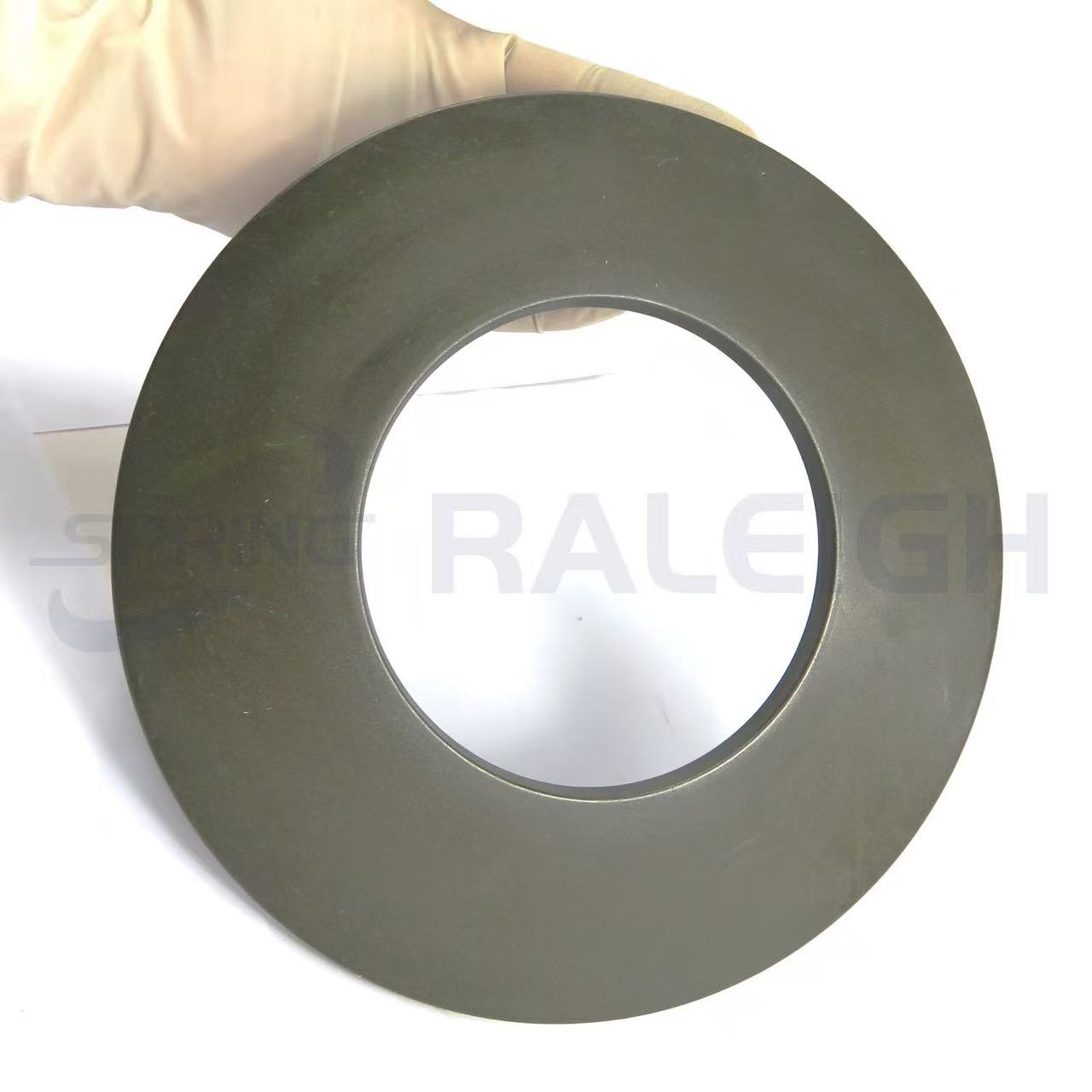

Manufacturing process of rubber coated injection ferrite magnet

Rubber coated injection ferrite magnets are widely used in various industries due to their unique properties and versatility. These magnets are known for their excellent magnetic strength, durability, and resistance to corrosion. In this blog post, Ningbo Zhonghang will delve into the manufacturing process of rubber coated injection ferrite magnets, exploring each step in detail.

1. Raw Material Selection:

The first step in the manufacturing process is the careful selection of raw materials. Ferrite powder, rubber compound, and other additives are chosen based on their quality, performance, and compatibility with the desired magnet specifications. The quality of the raw materials directly affects the final product's magnetic properties and overall performance.

2. Mixing and Compounding:

Once the raw materials are selected, they are mixed and compounded in precise proportions. This step involves blending the ferrite powder, rubber compound, and additives in a high-speed mixer. The mixing process ensures uniform distribution of the materials and enhances the magnet's magnetic strength and stability.

3. Injection Molding:

After the mixing and compounding process, the magnet compound is ready for injection molding. Injection molding is a widely used technique in the manufacturing of rubber coated ferrite magnets. The compound is injected into a mold cavity under high pressure and temperature. The mold is designed to give the magnet its desired shape and dimensions.

4. Vulcanization:

Once the magnet compound is injected into the mold, it undergoes a vulcanization process. Vulcanization involves subjecting the magnet to heat and pressure, which activates the cross-linking reaction in the rubber compound. This process enhances the magnet's mechanical strength, flexibility, and resistance to temperature variations.

5. Magnetization:

After the vulcanization process, the magnet is demolded and undergoes magnetization. Magnetization involves exposing the magnet to a strong magnetic field, aligning the magnetic domains within the material. This step is crucial for achieving the desired magnetic properties of the rubber coated injection ferrite magnet.

6. Coating:

To provide additional protection and enhance the magnet's performance, a rubber coating is applied to the magnet's surface. The coating material is carefully selected based on its compatibility with the magnet compound and the desired application. The coating process ensures the magnet's resistance to corrosion, moisture, and external impacts.

7. Quality Control:

Throughout the manufacturing process, strict quality control measures are implemented to ensure the magnets meet the required standards. Various tests, such as magnetic strength, dimensional accuracy, and visual inspection, are conducted to verify the magnet's quality and performance. Any defective magnets are rejected, and necessary adjustments are made to the manufacturing process.

Conclusion:

The manufacturing process of rubber coated injection ferrite magnets involves a series of carefully executed steps, from raw material selection to quality control. Each step plays a crucial role in determining the magnet's magnetic properties, durability, and overall performance. By understanding the intricacies of this process, manufacturers can produce high-quality rubber coated injection ferrite magnets that meet the diverse needs of various industries.

Zhonghang

nishant@sunny-magnet.com