Microwave Digestion for Metal Analysis: A Revolutionary Technique for Sample Preparation

Microwave digestion is a closed-vessel acid digestion technique that utilizes microwave energy to break down solid and liquid samples into a solution suitable for analysis. The process involves placing a sample in a high-pressure, chemically resistant vessel along with an appropriate acid or acid mixture. The vessel is then subjected to microwave radiation, which heats the contents rapidly and efficiently, promoting fast and complete digestion of the sample.

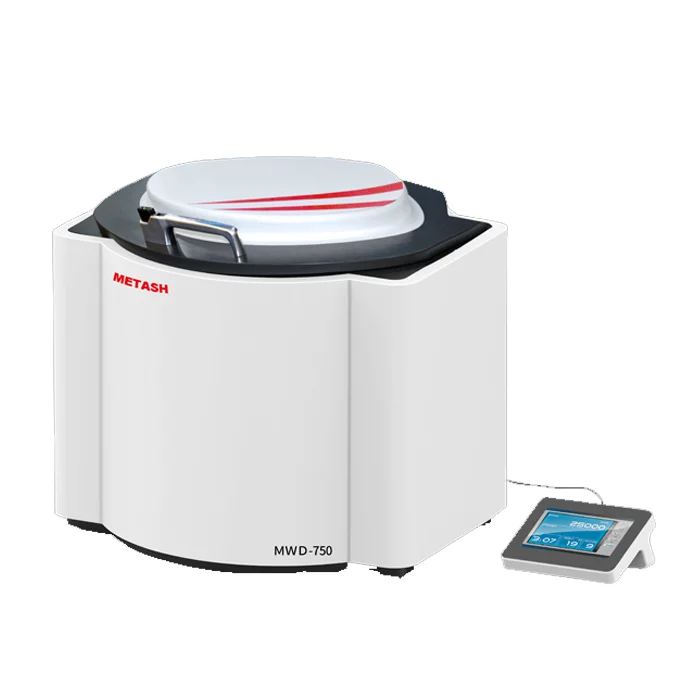

This method is commonly used as a sample preparation step for Inductively Coupled Plasma Mass Spectrometry (ICP-MS), Inductively Coupled Plasma Optical Emission Spectroscopy (ICP-OES), and Atomic Absorption Spectroscopy (AAS), all of which require liquid samples for accurate metals quantification. In this blog post, Metash will share the applications and benefits of microwave digestion for metals analysis, and how it can be optimized to provide greater speed, accuracy, and safety.

Benefits of Microwave Digestion for Metals Analysis

1. Faster Digestion Process

Compared to conventional hot plate or open-vessel digestion, microwave digestion significantly reduces digestion time. Traditional methods may take hours, while microwave digestion can often complete the process within minutes.

2. Improved Reproducibility and Accuracy

Microwave digestion provides a highly controlled environment where temperature and pressure are precisely regulated. This ensures uniform digestion, leading to reproducible results and minimizing sample contamination or loss.

3. Enhanced Safety Features

Since the digestion occurs in a closed vessel system, it minimizes the risk of acid fumes exposure and reduces the potential for sample loss due to evaporation. Many modern microwave digestion systems include built-in pressure and temperature sensors to prevent over-pressurization or overheating.

4. Reduced Acid Consumption

Microwave digestion typically requires lower acid volumes than traditional methods, leading to reduced reagent costs and less hazardous waste production.

5. Ability to Handle Diverse Sample Matrices

From biological tissues and food samples to environmental and industrial materials, microwave digestion can effectively break down complex matrices that are challenging for conventional digestion methods.

Applications of Microwave Digestion for Metals Analysis

1. Environmental Monitoring

Regulatory agencies require the analysis of heavy metals in air, water, soil, and sediments to ensure compliance with environmental safety standards. Microwave digestion allows for rapid and accurate preparation of these samples, making it indispensable in environmental laboratories.

2. Pharmaceutical Industry

In pharmaceutical manufacturing, trace metals can impact drug stability and safety. Microwave digestion is widely used for the preparation of samples before metal analysis using ICP-MS or ICP-OES, ensuring compliance with pharmacopeial guidelines such as USP <232> and ICH Q3D.

3. Food and Beverage Testing

Ensuring food safety involves analyzing metal content in raw materials and processed products. Microwave digestion plays a critical role in preparing food samples for metal detection, helping manufacturers comply with regulatory standards set by organizations like the FDA and EFSA.

4. Mining and Metallurgy

Accurate metal composition analysis is essential in the mining and metallurgy sectors. Microwave digestion helps dissolve ores, alloys, and geological samples efficiently, ensuring precise quantification of valuable and toxic metals.

5. Biomedical and Clinical Research

The determination of trace metals in biological samples such as blood, urine, and tissues is critical for medical diagnostics and toxicology studies. Microwave digestion ensures complete sample decomposition, providing reliable results for further analysis.

How to Optimize Microwave Digestion for Metals Analysis?

To achieve the best results with microwave digestion, consider the following factors:

- Acid Selection: The choice of acid depends on the sample type. Common acids include nitric acid (HNO₃), hydrochloric acid (HCl), sulfuric acid (H₂SO₄), and hydrofluoric acid (HF) for silicate-based samples.

- Proper Vessel Selection: Use digestion vessels that can withstand high pressure and temperature while ensuring chemical compatibility with the acid used.

- Temperature and Pressure Control: Modern microwave digestion systems allow precise control over these parameters, ensuring complete sample breakdown without excessive reagent consumption.

- Sample Homogenization: To improve digestion efficiency, ensure that samples are finely ground and properly mixed before digestion.

Conclusion

Microwave digestion for metals analysis has become a gold standard in analytical chemistry due to its efficiency, safety, and ability to handle complex sample matrices. Whether used in environmental science, pharmaceuticals, or food safety, this technique significantly improves the accuracy and reproducibility of metal quantification. By optimizing digestion conditions and using the right analytical tools, laboratories can achieve high-quality results while reducing analysis time and operational costs.

As the demand for precise and rapid metals analysis continues to grow, microwave digestion remains a crucial technology in modern analytical laboratories. Investing in a high-quality microwave digestion system can provide long-term benefits, ensuring compliance with regulatory standards and enhancing laboratory productivity.

https://www.metashcorp.com/Applications-of-Microwave-Digestion-for-Metals-Analysis.html

www.metashcorp.com

Metash