Understanding Press Brake Die and Punch Types: Which One Suits Your Metal Bending Needs?

When it comes to precision metal bending, press brake tooling plays a crucial role in achieving accurate and consistent results. Whether you are working with sheet metal fabrication, industrial manufacturing, or custom metalwork, selecting the right press brake die and punch is essential for optimizing productivity and ensuring high-quality bends.

At AE Tooling, we specialize in designing and manufacturing high-end press brake tooling for both press brake manufacturers and fabrication companies. Our expertise allows us to develop tooling solutions that enhance precision, durability, and efficiency in metal bending operations. In this article, we will explore the different types of press brake dies and punches and help you determine which one best suits your metal bending needs.

1. Understanding Press Brake Punches and Dies

A press brake punch and die work together to shape metal sheets into precise angles and forms. The punch applies downward force, pressing the metal into the die, which determines the final shape of the bend. Different punch and die types are used to achieve various bending techniques.

2. Common Types of Press Brake Punches

A. Straight Punch

-

Features a simple straight-edge design.

-

Used for standard V-bending applications.

-

Ideal for thin to medium-gauge sheet metal.

B. Gooseneck Punch

-

Designed with a curved profile to allow for deeper bends.

-

Prevents interference when bending complex shapes such as U-channels or deep boxes.

-

Ideal for forming intricate metal components.

C. Hemming Punch

-

Used for hemming operations, where a metal sheet is folded over itself for added strength.

-

Common in automotive and aerospace applications where reinforced edges are needed.

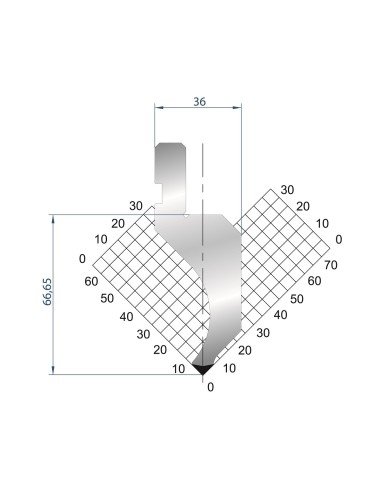

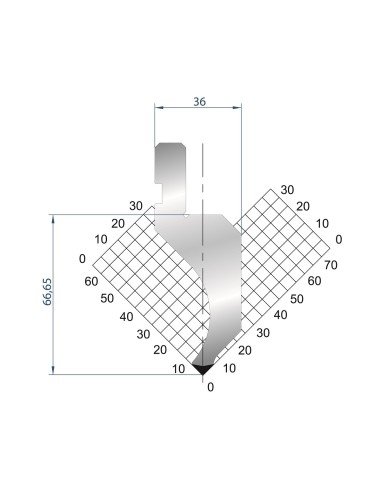

D. Acute Angle Punch

-

Creates sharper bends (less than 90 degrees).

-

Suitable for applications requiring tight bend radii.

At AE Tooling, we manufacture high-precision press brake punches with premium-grade materials to ensure extended tool life and optimal bending accuracy.

3. Common Types of Press Brake Dies

A. V-Dies (Standard Die for V-Bending)

-

The most commonly used die type.

-

Available in various sizes (V-openings) to accommodate different material thicknesses.

-

The wider the V-opening, the less force is required for bending.

B. U-Dies

-

Designed for forming U-shaped bends.

-

Commonly used in structural metalwork.

C. Radius Dies

-

Used to create smooth, rounded bends instead of sharp angles.

-

Ideal for aerospace and automotive applications where stress reduction is crucial.

D. Offset Dies

-

Designed to create two bends in a single stroke, forming an offset shape.

-

Ideal for producing parts with step-down profiles.

E. Gooseneck Dies

-

Designed for use with gooseneck punches to enable deep bends without tool interference.

At AE Tooling, our precision-crafted dies are engineered to meet the highest industry standards, ensuring superior bending accuracy and tool longevity.

4. Choosing the Right Punch and Die for Your Application

To determine the best press brake tooling for your needs, consider the following factors:

✅ Material Type & Thickness – Different metals (steel, aluminum, stainless steel) require different punch and die configurations.

✅ Bend Angle & Shape – Ensure your tooling selection matches the desired bend profile.

✅ Production Volume – High-production environments may require hardened tooling for extended durability.

✅ Press Brake Capacity – Make sure the punch and die are compatible with your machine’s tonnage and bending force.

At AE Tooling, we provide customized tooling solutions tailored to specific metal bending applications, helping manufacturers enhance efficiency and precision in their production processes.

5. Why Choose AE Tooling for Your Press Brake Tooling Needs?

With years of expertise in the press brake tooling industry, AE Tooling is a trusted partner for fabrication companies and press brake manufacturers worldwide. Our advantages include:

✔ High-quality materials for enhanced durability and precision.

✔ Custom tooling solutions designed to meet specific industry requirements.

✔ Advanced manufacturing techniques ensuring consistent performance.

✔ Exceptional customer support to help optimize your bending operations.

Conclusion

Selecting the right press brake punch and die is essential for achieving precise and efficient metal bending results. By understanding the different punch and die types, you can choose the ideal tooling for your specific application, improving productivity and reducing errors.

At AE Tooling, we are committed to providing high-end press brake tooling solutions that meet the highest standards of performance and durability. Contact us today to find the perfect tooling for your metal bending needs!

www.aetooling.com

AE Tooling