Five-Axis Machining Centers Explained: From Basic Functions to Complex Applications

In the rapidly evolving world of precision manufacturing, Five-Axis Machining Centers have become a cornerstone of modern production across industries such as aerospace, automotive, mold making, medical devices, and high-end tooling. Their ability to perform intricate operations with extraordinary accuracy and efficiency has elevated them well beyond traditional three-axis machines.

In this blog, we’ll explore what makes five-axis machining centers so powerful—delving into their basic functions, key advantages, and real-world applications—while also highlighting how companies like Zhiquan Electromechanical Equipment Co., Ltd. are playing a pivotal role in bringing advanced machining capabilities to global markets.

What Is a Five-Axis Machining Center?

A five-axis machining center is a computer-controlled cutting machine capable of moving a tool or a part in five different axes simultaneously—typically the X, Y, Z linear axes plus two rotational axes (A and B or C). This enables the machine to approach the workpiece from virtually any angle, minimizing the need for repositioning and multiple setups.

Basic Movements:

X, Y, Z axes: Linear movement in three directions.

A axis: Rotation around the X-axis.

B or C axis: Rotation around the Y or Z-axis, depending on the configuration.

This flexibility translates into improved efficiency, better surface finishes, and the ability to machine complex geometries in a single setup.

Benefits of Five-Axis Machining

1. Reduced Setup Time

Since the workpiece can be machined from all angles in one go, fewer setups are needed—dramatically improving production efficiency.

2. Enhanced Accuracy

Less repositioning means less chance for error. This is critical in industries where even a fraction of a millimeter deviation is unacceptable.

3. Superior Surface Finish

Continuous tool engagement reduces vibration and improves surface quality, especially in contouring and sculpted parts.

4. Complex Geometry Capability

From turbine blades to orthopedic implants, five-axis machines can produce intricate shapes that are virtually impossible on three-axis machines.

Applications Across Industries

Aerospace

Precision and lightweight component manufacturing for turbines, engine housings, and structural components demand five-axis machining to meet strict tolerances and safety standards.

Automotive

High-performance components such as cylinder heads, engine blocks, and complex mold designs are best suited for five-axis processes, offering faster cycle times and improved repeatability.

Mold & Die

Five-axis centers are a game-changer for mold makers, enabling deep cavity milling, undercuts, and compound angles in a single clamping.

Medical Devices

From bone plates to prosthetics, the medical field demands compact, complex, and highly accurate parts that only five-axis machines can deliver.

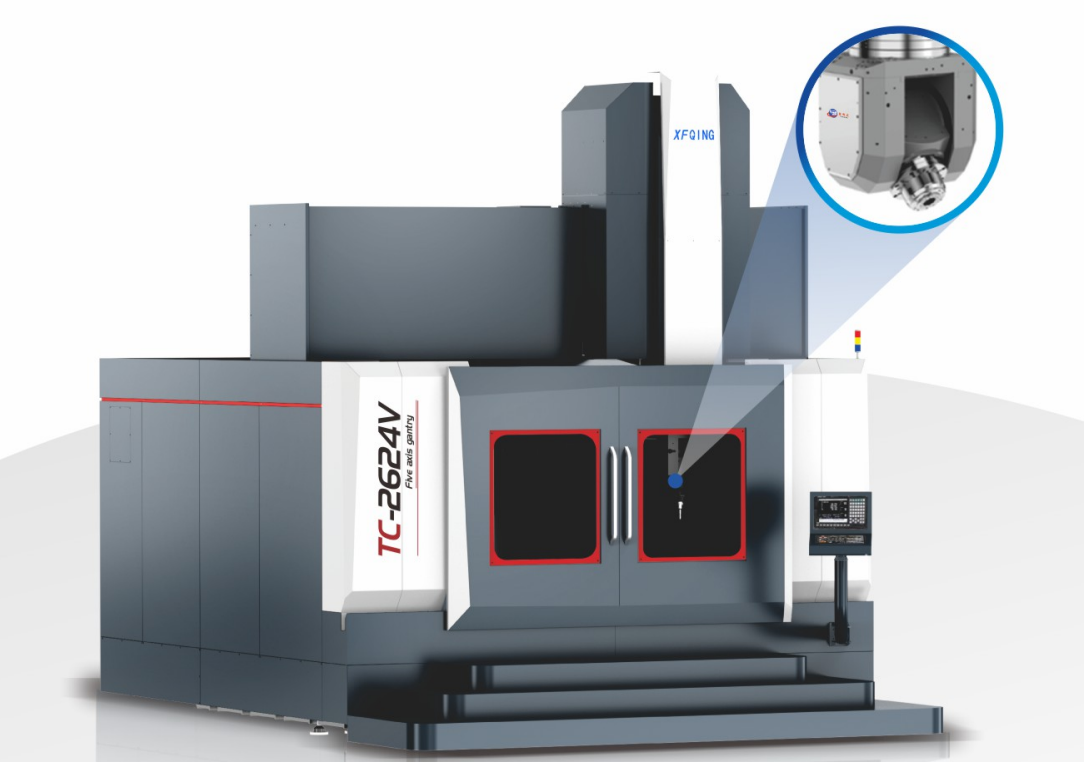

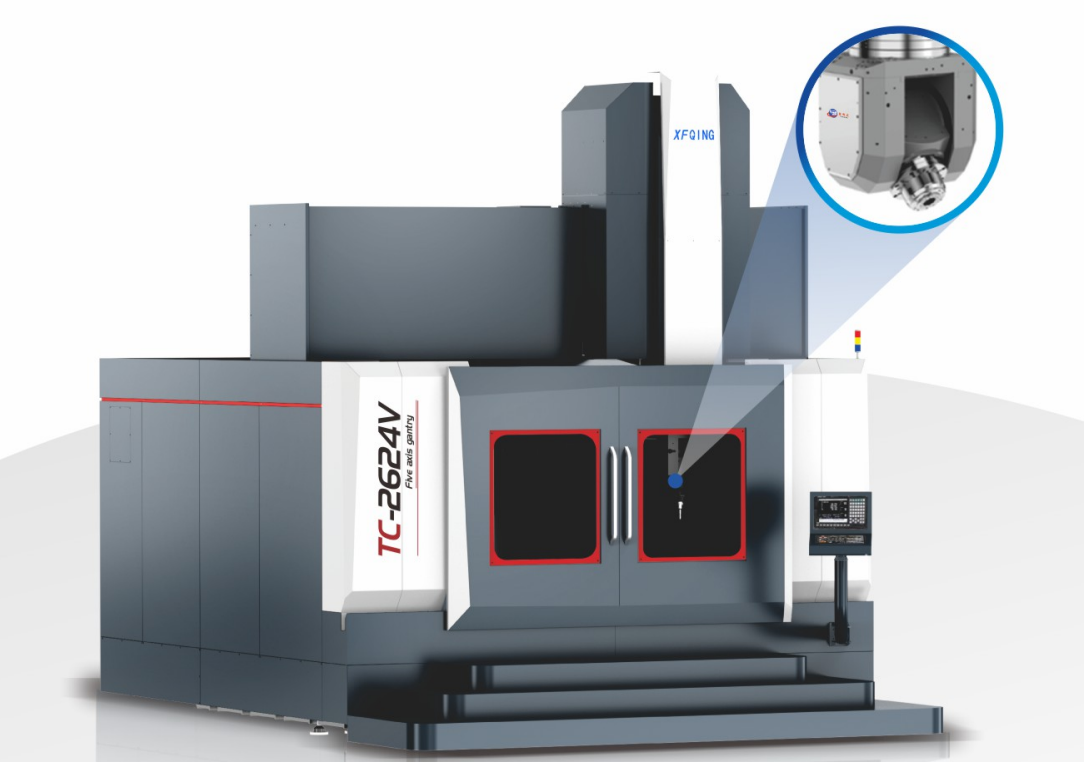

Zhiquan Electromechanical Equipment Co., Ltd.: Driving CNC Innovation Forward

As the demand for precision and productivity rises, Zhiquan Electromechanical Equipment Co., Ltd. stands at the forefront of innovation in CNC machining technology. With a strong foundation in CNC machining centers, wire cutting machines, EDM forming machines, and milling equipment, Zhiquan is committed to delivering high-quality, cost-effective, and performance-driven solutions.

Why Choose Zhiquan?

Advanced Product Line: Zhiquan offers a range of CNC and EDM equipment tailored to modern industrial needs, including multi-axis configurations for complex parts.

About Author