Exploring the Versatile World of 3D Printing: Unveiling the Ideal Plastics for the Job

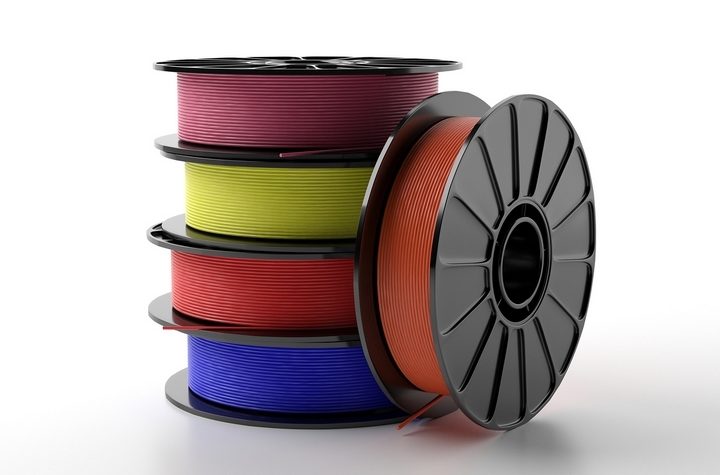

In the realm of 3D printing, the choice of plastic material plays a pivotal role in determining the quality, strength, and functionality of the printed objects. With a wide array of plastic options available, it's essential to understand the characteristics and applications of different plastics used in 3D printing. In this article, we delve into the fascinating world of 3D printing plastics, exploring their unique properties and highlighting the ideal materials for various applications.

- Polylactic Acid (PLA):

PLA, derived from renewable resources such as cornstarch or sugarcane, is one of the most popular choices for 3D printing. It offers a range of benefits, including low toxicity, ease of use, and biodegradability. PLA is commonly used for prototyping, educational purposes, and creating intricate models due to its excellent printability and vibrant color options. However, it may not be suitable for functional parts requiring high strength or heat resistance. - Acrylonitrile Butadiene Styrene (ABS):

ABS is a widely used thermoplastic known for its durability and impact resistance. It is commonly employed in automotive, aerospace, and consumer electronics industries. ABS exhibits better heat resistance compared to PLA, making it suitable for functional parts subjected to higher temperatures. However, it emits potentially harmful fumes during printing, necessitating proper ventilation. Additionally, ABS requires a heated print bed to minimize warping. - Polyethylene Terephthalate Glycol (PETG):

PETG strikes a balance between the ease of printing and mechanical properties. It offers excellent layer adhesion, impact resistance, and transparency. PETG is often preferred for functional parts, mechanical components, and containers due to its durability and chemical resistance. Moreover, it is less prone to warping compared to ABS, making it a popular choice for larger prints. - Nylon:

Nylon, a versatile engineering thermoplastic, exhibits exceptional strength, flexibility, and durability. It is commonly used in industrial applications, including automotive parts, gears, and functional prototypes. Nylon's high melting point and resistance to chemicals make it suitable for demanding environments. However, it requires specific printing conditions, such as a heated chamber, to prevent warping and achieve optimal results. - Polycarbonate (PC):

Polycarbonate is a robust and transparent thermoplastic known for its high impact resistance and heat tolerance. It finds applications in industries such as aerospace, automotive, and medical, where strength and clarity are crucial. PC is suitable for functional prototypes, protective components, and transparent enclosures. However, it requires a heated print bed and an enclosed chamber to minimize warping and ensure successful prints.

Conclusion:

The world of 3D printing offers a vast range of plastic materials, each with its unique properties and applications. Understanding the characteristics of different plastics is essential for selecting the ideal material for specific projects. Whether you're creating prototypes, functional parts, or artistic designs, considering factors like strength, heat resistance, printability, and durability will help you make informed choices. Embrace the possibilities of 3D printing by exploring the diverse range of plastics available and unlocking the potential for innovation in various industries.