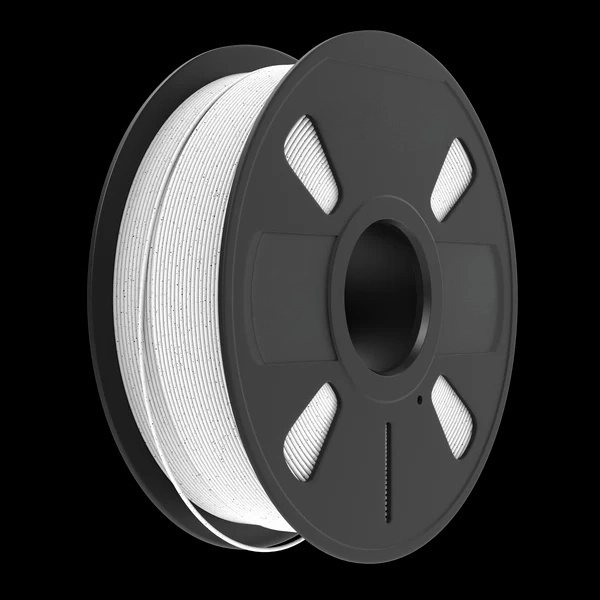

How Marble PLA Resin Enhances 3D Printing Products with Realistic Stone Texture and High Layer Strength

In the rapidly evolving world of additive manufacturing, material innovation is crucial for achieving high-quality, durable, and aesthetically appealing 3D printed products. Marble PLA resin, such as Ubest’s UBMP-2, has emerged as a leading solution for designers and manufacturers seeking realistic stone textures, high layer strength, and reliable extrusion performance. By combining biodegradable polylactic acid with mineral fillers, this advanced material enables the creation of 3D printed objects that replicate the visual and tactile qualities of natural marble, while offering superior mechanical performance.

Realistic Stone Texture for High-End Applications

One of the most compelling advantages of Marble PLA resin is its ability to produce a highly realistic marble effect. Unlike standard PLA filaments, UBMP-2 integrates micro-mineral particles that simulate the color variations, veining, and natural patterns of stone. This makes it ideal for architectural models, decorative items, tabletop designs, and custom prototypes, providing a premium finish that appeals to both professional designers and hobbyists.

The filament’s consistent diameter and smooth extrusion ensure that layers align precisely, preserving the detailed marble-like surface. With proper print settings, surfaces require minimal post-processing, reducing time and effort while maintaining a professional finish.

High Layer Strength for Structural Integrity

Beyond aesthetics, layer adhesion and mechanical performance are critical factors in 3D printing. UBMP-2 Marble PLA exhibits excellent interlayer bonding, allowing printed products to withstand mechanical stress and functional use. Its high toughness and strength make it suitable for creating durable decorative components, structural prototypes, and functional parts that require both visual appeal and reliability.

High layer strength also allows for faster printing speeds without compromising quality. By maintaining strong adhesion between layers, Marble PLA reduces warping, delamination, and weak points commonly associated with standard PLA, ensuring consistent performance across various printer models and extrusion setups.

Biodegradable and Sustainable Material Advantages

UBMP-2 is a fully biodegradable PLA resin derived from renewable plant sources such as corn starch. This aligns with growing environmental concerns and sustainability standards in the additive manufacturing industry. After disposal, the material can naturally decompose into carbon dioxide and water under microbial activity, achieving zero pollution and eco-friendly production goals.

The combination of high performance and sustainability makes Marble PLA resin an attractive option for designers and manufacturers seeking to meet green manufacturing standards while producing premium products.

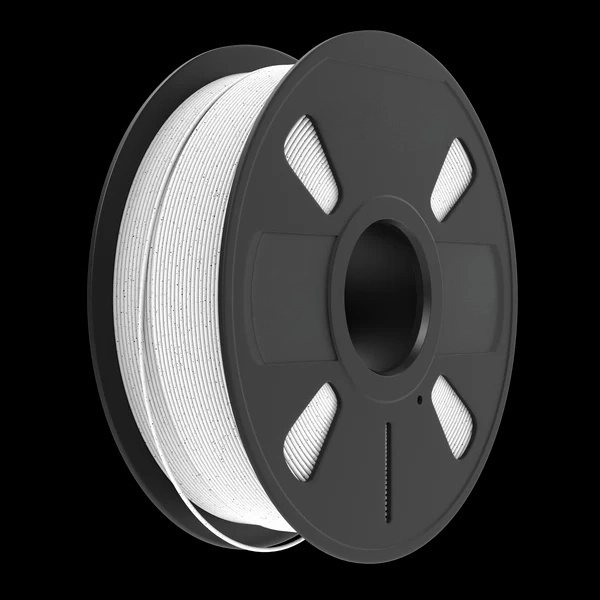

Printing Compatibility and Ease of Use

UBMP-2 is designed for use with standard extrusion-based 3D printers, ensuring broad compatibility and easy adoption. Its stable extrusion, controlled flow, and precise diameter enable smooth layer deposition, minimizing printer jams and enhancing repeatability for high-volume production.

Key technical benefits include:

-

Stable filament diameter for consistent extrusion

-

Excellent toughness and impact resistance for functional parts

-

High-speed printing capability without compromising surface quality

-

Compatibility with standard 3D printing extruders for ease of integration

These features make UBMP-2 ideal for both commercial and hobbyist applications, delivering a professional-grade finish and reliable mechanical performance.

Customization and Application Potential

Designers and manufacturers can leverage Marble PLA resin to expand creative possibilities:

-

Decorative and architectural models: Realistic marble surfaces enhance visual appeal.

-

Functional components: High layer strength ensures structural reliability.

-

Prototyping: Accurate extrusion and consistent layer adhesion allow precise testing.

-

Educational tools and display models: Lightweight yet durable parts improve usability and safety.

By incorporating UBMP-2, businesses can deliver products that are visually striking, mechanically reliable, and environmentally responsible.

FAQ – Marble PLA Resin UBMP-2

Q1: Can Marble PLA resin be used on any standard 3D printer?

A1: Yes, UBMP-2 is compatible with most extrusion-based printers, providing smooth and reliable printing.

Q2: What makes Marble PLA stronger than standard PLA?

A2: Its modified formulation improves interlayer adhesion, toughness, and mechanical strength, making it suitable for functional and decorative parts.

Q3: Is Marble PLA environmentally friendly?

A3: Yes, it is fully biodegradable and derived from renewable plant sources, producing zero pollution upon decomposition.

Q4: Can Marble PLA resin produce detailed marble-like textures?

A4: Absolutely. The micro-mineral additives replicate natural marble patterns, providing a high-end appearance.

Conclusion

Marble PLA resin UBMP-2 from Ubest is revolutionizing 3D printing by combining realistic stone texture, high layer strength, and sustainable materials. Its durable performance, ease of use, and visual appeal make it an ideal choice for designers, manufacturers, and hobbyists seeking premium-quality 3D printed products. With UBMP-2, 3D printing transcends standard PLA limitations, delivering functional, aesthetic, and environmentally conscious solutions for a wide range of applications worldwide.

www.wxubest.com

Wuxi Ubest New Material Technology Co., Ltd.