Understanding Dry Mechanical Seals: What They Are and How They Work

Dry mechanical seals are an essential component in many industrial applications, including pumps, compressors, and mixers. They are designed to prevent the leakage of fluids and gases between two surfaces, typically a rotating shaft and a stationary housing. In this article, we will explore what dry mechanical seals are, how they work, and their advantages over other types of seals.

What is a Dry Mechanical Seal?

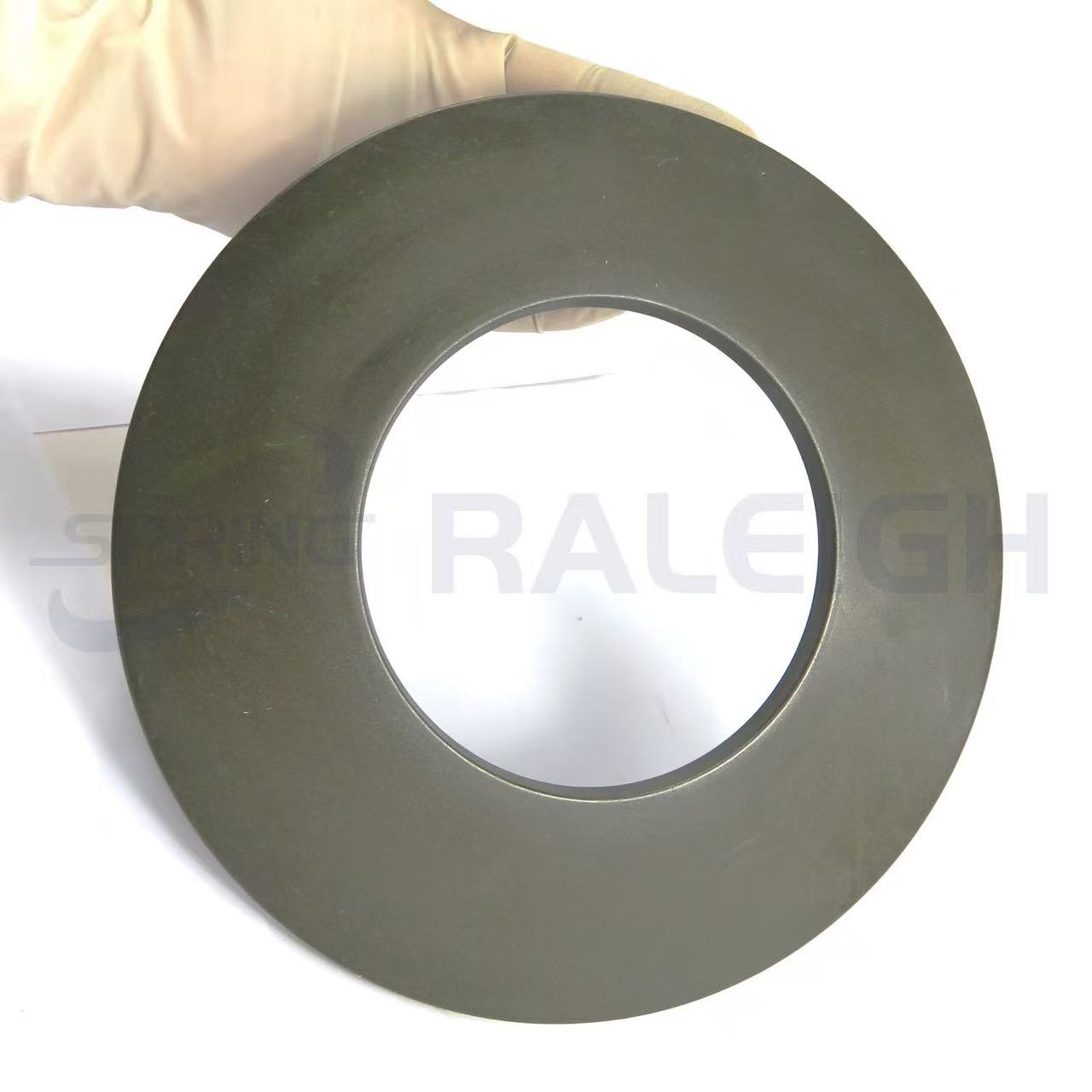

A dry mechanical seal is a type of seal that uses two flat faces, one stationary and one rotating, to create a barrier between two surfaces. The seal faces are typically made of hard materials such as silicon carbide, tungsten carbide, or ceramic, and are held together by a spring or other mechanism. The seal faces are designed to be in close contact with each other, creating a tight seal that prevents the leakage of fluids or gases.

How Does a Dry Mechanical Seal Work?

Dry mechanical seals work by creating a barrier between two surfaces, preventing the leakage of fluids or gases. The seal faces are held together by a spring or other mechanism, which creates a force that keeps the faces in contact with each other. As the rotating shaft moves, the seal faces rotate with it, maintaining contact and preventing leakage.

One of the key advantages of dry mechanical seals is that they do not require any external lubrication. This is because the seal faces are designed to be in close contact with each other, creating a self-lubricating effect. This reduces the risk of contamination and makes dry mechanical seals ideal for use in applications where contamination is a concern.

Advantages of Dry Mechanical Seals

Dry mechanical seals offer several advantages over other types of seals. One of the main advantages is their ability to operate without external lubrication. This reduces the risk of contamination and makes them ideal for use in applications where contamination is a concern.

Another advantage of dry mechanical seals is their ability to handle high temperatures and pressures. They are designed to withstand extreme conditions, making them suitable for use in a wide range of industrial applications.

In addition, dry mechanical seals are easy to install and maintain. They require minimal maintenance and can be easily replaced when necessary, reducing downtime and increasing productivity.

Conclusion

Dry mechanical seals are an essential component in many industrial applications, providing a reliable and efficient way to prevent the leakage of fluids and gases. They offer several advantages over other types of seals, including their ability to operate without external lubrication, their ability to handle high temperatures and pressures, and their ease of installation and maintenance. If you are looking for a reliable and efficient way to prevent leakage in your industrial application, consider using a dry mechanical seal.